-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

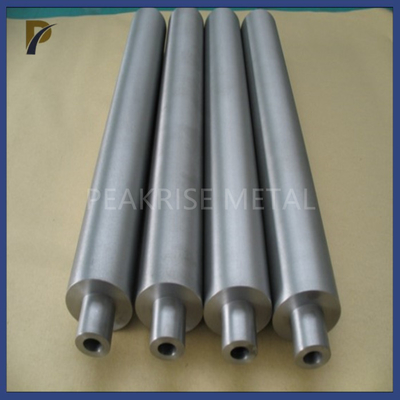

High Purity 99.95% Molybdenum Electrode Rod For Glass Electric Melting Furnace

| Name | High Purity 99.95% Molybdenum Electrode Of Glass Electric Melting Furnace | Material | Pure Molybdenum |

|---|---|---|---|

| Purity | Min.99.95% | Shape | Rod |

| Diameter | 4~120mm | Length | <1500mm |

| Surface | Bright,polished | Export Port | Any Port In China |

| Highlight | 99.95% Molybdenum Electrode,Melting Furnace Molybdenum Electrode,120mm molybdenum rod |

||

Molybdenum Electrode Of Glass Electric Melting Furnace With High Purity 99.95%

1. High Purity 99.95% Molybdenum Electrode For Glass Electric Melting Furnace Description:

In a glass furnace, the surface temperature of the molybdenum electrode is generally 200 ℃ higher than the temperature of the molten glass.

If the surface temperature of the molybdenum electrode reaches 2000 ℃. Then the loss of the molybdenum electrode is also larger. The surface temperature of the molybdenum electrode is related to the surface current density applied to the molybdenum electrode. Therefore, the higher the surface current density, the faster the loss.

We suggest that the surface current density of molybdenum electrodes in general electric kilns should be moderate at 1.0-0.7A/cm2. Lower surface current densities should be used when furnaces require higher glass quality and longer electrode life. The highest surface current density of molybdenum electrode should not be greater than 2A/cm2.

The figure below shows the suitable insertion length of the molybdenum electrode in the glass. Improper insertion length will lead to the rapid oxidation of the molybdenum electrode due to high temperature.

![]()

![]()

![]()

2. Molybdenum Electrode Of Glass Electric Melting Furnace With High Purity 99.95%:

|

High Purity 99.95% Molybdenum Electrode Of Glass Electric Melting Furnace: |

|||||

| Dia [mm] |

tolerance [mm] |

length [mm] |

Surface | Straightness [per m] |

Approx weight [kg/m] |

| 4.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.128 |

| 10.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.801 |

| 20.00 | +/- 0.020 | 2000 | polished | <2.5 | 3.204 |

| 25.00 | +/- 0.040 | 2000 | polished | <2.5 | 5.007 |

| 30.00 | +/- 0.300 | 2000 | Polished | <1.5 | 7.210 |

| 40.00 | +/- 0.300 | 2000 | Polished | <1.5 | 12.818 |

| 50.00 | +/- 0.400 | 2000 | Polished | <1.5 | 20.654 |

| 60.00 | +/- 0.400 | 2000 | Polished | <1.5 | 28.840 |

| 63.50 | +/- 0.400 | 2000 | Polished | <1.5 | 32.303 |

| 70.00 | +/- 0.400 | 2000 | Polished | <1.5 | 39.254 |

| 80.00 | +/- 1.000 | 2000 | Polished | <2.5 | 51.271 |

| 90.00 | +/- 1.000 | 2000 | Polished | <2.5 | 64.890 |

| 100.00 | +/- 1.000 | 2000 | Polished | <2.5 | 80.111 |

| 120.00 | +/- 2.000 | 2000 | Polished | <2.5 | 115.359 |

3. Performance optimization of molybdenum electrodes for glass electric melting furnaces

The failure mode of molybdenum electrodes used in glass electric melting furnaces is a complex phenomenon that depends on the chemical composition of the electrodes, the current density, the chemical composition of the glass melt, etc. Its performance can be optimized by surface finish, impurity content control, etc.

1). Surface finish

The diameter tolerance and surface finish of the molybdenum electrode can be ensured by machining and grinding the surface, so that when it is installed in the electrode holder, impurities and foreign matter do not contaminate the surface.

2). Impurity content control

Impurities in molybdenum powder can directly cause electrode cracks or hidden cracks; at the same time, C, N, etc. will also cause bubbles in the glass liquid, affecting the quality of the glass; metal elements such as Ti, Ni, Cu, Cd will color the glass.

3). Molybdenum powder particle size control

According to production practice experience and data analysis, it is known that molybdenum powder with medium particle size and close to normal distribution is suitable for the production of high-quality molybdenum electrode products.

4). Molybdenum electrode sintering

The temperature difference between the inside and outside of the molybdenum electrode blank is minimized by adopting a slow and steady temperature rise and a step-by-step heat preservation system to prevent defects such as internal cracks caused by excessive thermal stress. Appropriate heat preservation temperature and time can ensure a fine and uniform grain structure.

5). Molybdenum electrode forging

The key to producing high-quality molybdenum electrodes is to use a suitable forging process, especially suitable forging temperature, final forging temperature, deformation and pass deformation.

Please click below button for learn more our products.

![]()