-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

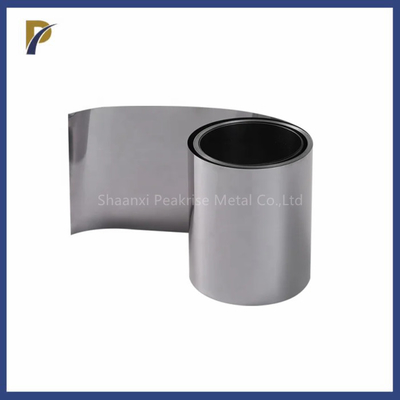

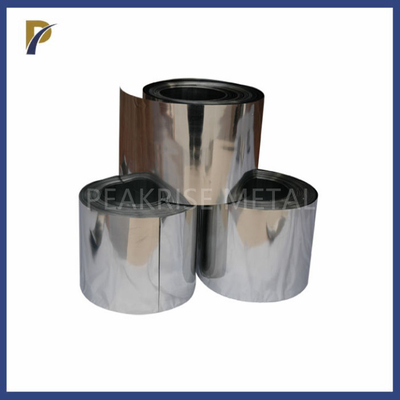

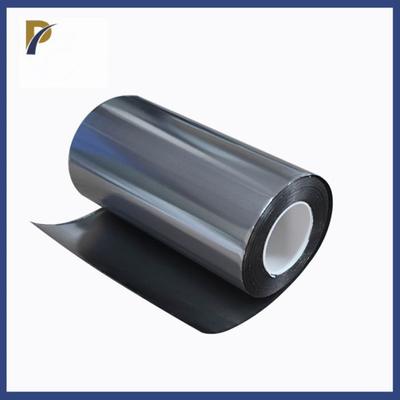

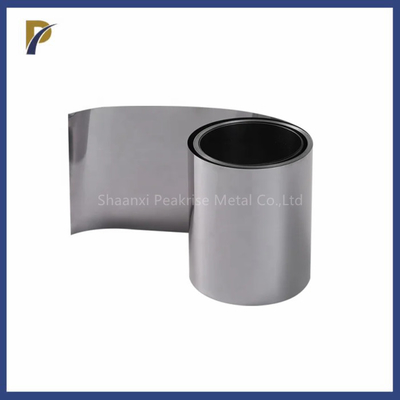

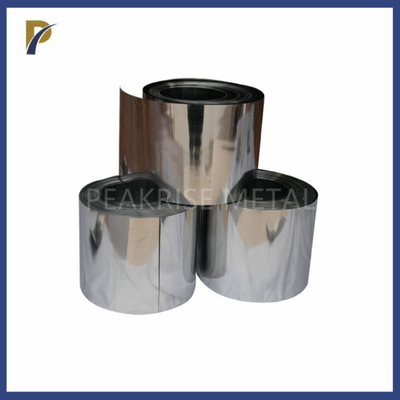

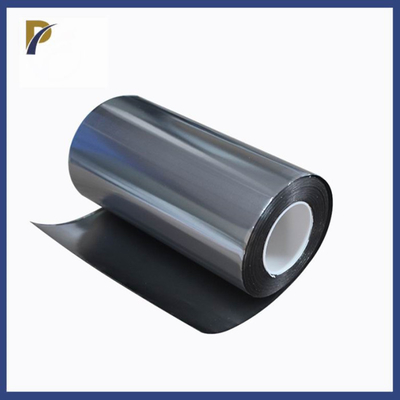

0.03mm 0.05mm 99.95% Purity Tantalum Foil / Strip RO5200 Ta1

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Tantalum Foil Tantalum Strip | Purity | 99.95% |

|---|---|---|---|

| Grade | RO5200,RO5252,RO5255 | Thickness | Min 0.025mm |

| Width | <200mm | Surface | Bright |

| Standard | ASTM B708 | Color | Metallic Color |

| Highlight | Bright Surface Tantalum Strip,99.95% Purity Tantalum Foil,0.05mm Tantalum Foil |

||

0.03mm,0.05mm 99.95% Purity Tantalum Foil Tantalum Strip RO5200 Ta1

1. Specification of Tantalum Foil Tantalum Strip :

Tantalum foil is usually made of high-purity tantalum metal, and its purity can reach more than 99.95%. High-purity tantalum foil ensures the stability of its chemical properties and the reliability of its mechanical properties.

Ta foil

Thickness:0.025--1.0mm

Width: max 200mm

Purity:99.95%min

Grade: RO5200, RO5252, RO5255

Standard: ASTM B708

Surface: bright

Condition: annealed

| Name | Thickness | Width | Length |

| Foil | 0.03~0.09mm | 30-200mm | >200mm |

| Sheet | 0.1-2.0mm | 30- 600mm | 30-1000mm |

| Plate | 2.0-50mm | 30- 600mm | <2500mm |

| Grade | Main elements | Impurity content less than % | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Remain | —— | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 |

| Ta2 | Remain | —— | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.03 | 0.01 | 0.0015 | 0.01 |

| TaNb3 | Remain | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.03 | 0.01 | 0.0015 | 0.01 |

| TaNb20 | Remain | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.03 | 0.01 | 0.0015 | 0.01 |

| Ta2.5W | Remain | 0.005 | 0.005 | 0.002 | 3 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 | |

| Ta10W | Remain | 0.005 | 0.005 | 0.002 | 11 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 | |

2.Advantage of Tantalum Foil Tantalum Strip :

Corrosion resistance: Tantalum foil has excellent corrosion resistance to most common chemicals, including acids, alkalis and salt solutions. This makes tantalum foil ideal for use in corrosive environments such as the chemical industry, electrochemical applications and electrolysis in acidic solutions.

High Melting Point: Tantalum has a very high melting point, about 2996 degrees Celsius. Therefore, tantalum foil can maintain its structural integrity and physical properties in high temperature environments. This makes tantalum foil excellent in high temperature applications such as aerospace, nuclear industry and high temperature reactors.

Excellent conductivity: Tantalum is a good conductive material, and tantalum foil has excellent conductivity, which is higher than many other metals. This makes tantalum foil useful in applications such as electronics, circuits and electrodes.

Biocompatibility: Tantalum foil has good biocompatibility to human tissue, which makes it widely used in the medical field, such as the manufacture of artificial joints, implants and medical devices.

High strength and wear resistance: Although tantalum foil is a thin sheet material, it has good strength and wear resistance. This allows it to function in applications requiring high strength and durability.

3. Application of Tantalum Foil Tantalum Strip:

Chemical industry, Electronic industry, Aerospace industry, Aviation industry, Capacitors, High-temperature furnace parts, Semiconductor, Sputtering targets , Relative devices, And widely applied to electronics, metallurgy, chemical, pharmacy, aerospace and other fields.

4. Package & Shipping :

![]()

![]()

Please click below button for learn more our products.

![]()