-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

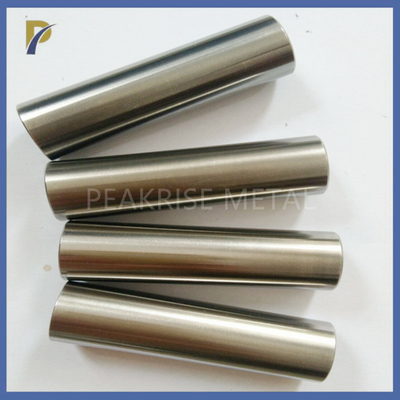

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

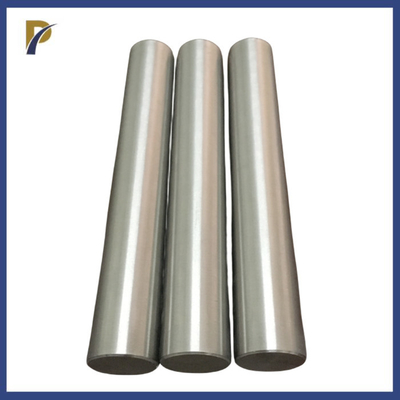

30%W Molybdenum Tungsten Steel Rod 30mm Diameter Excellent Electrical Conductivity

| Features | Excellent Electrical Conductivity | Name | 30%W Tungsten Molybdenum Alloy Rod Diameter30mm |

|---|---|---|---|

| Material | W-Mo Alloy | W Content | 30% |

| Size | Dia 30mm | Surface | Bright |

| Export Port | Any Port In China | Package | Plywood Case |

| Highlight | Molybdenum Tungsten Steel Rod,Tungsten Steel Rod 30mm |

||

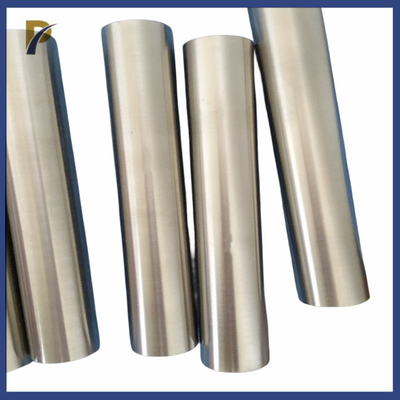

30%W Tungsten Molybdenum Alloy Rod Diameter 30mm

1. Material description of 30%W Tungsten Molybdenum Alloy Rod Diameter 30m:

Tungsten-molybdenum alloy has the common characteristics of tungsten and molybdenum metal, and has good high temperature stability, resistivity and good processing performance under vacuum or inert gas protection.

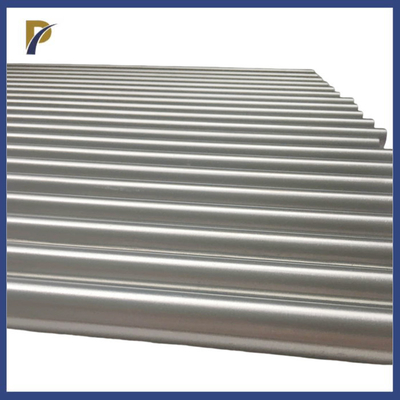

2. Size of 30%W Tungsten Molybdenum Alloy Rod Diameter 30m:

Diameter 5~150mm

Length <2000mm

Or can process as per customer request.

![]()

![]()

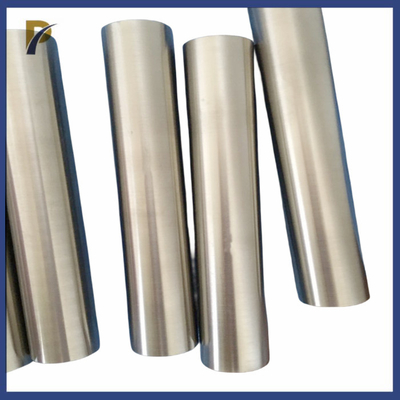

3. Production method of 30%W Tungsten Molybdenum Alloy Rod Diameter 30m:

Preparation method The molybdenum-tungsten alloy billet production methods include powder metallurgy, vacuum arc melting and vacuum electron bombardment melting. The powder metallurgy method is the most widely used, because the method is simple and can obtain alloy ingots with fine grains, which is conducive to plastic processing. The main process of powder metallurgy is: mechanically mixing molybdenum powder and tungsten powder in proportion; pressing into original billet by mechanical press or isostatic pressing; then sintering into alloy billet in a high-temperature sintering furnace with hydrogen. The sintering temperature increases with the increase of tungsten content, and its range is between 2150 and 2300 °C. Finally, the sintered billet is rolled or forged into a product.

4. Chemical of 30%W Tungsten Molybdenum Alloy Rod Diameter 30m:

| Quantitative analysis | ||||||||||

| Element | W | Mo | Fe | Si | Ca | Mg | P | C | O | Al |

| Concentration(%) | 30 | 70 | 0.001 | 0.002 | 0.0006 | 0.0006 | 0.002 | 0.003 | 0.003 | 0.004 |

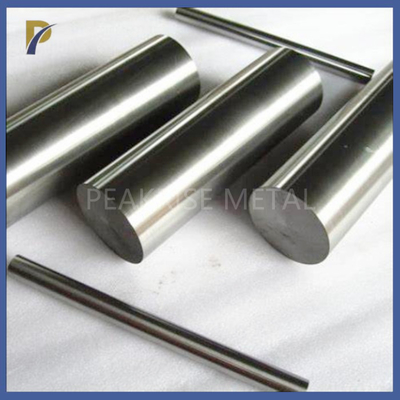

5. Temperature characteristics of 30%W Tungsten Molybdenum Alloy Rod Diameter 30m:

Properties (1) The melting point of molybdenum-tungsten alloy increases with the increase of tungsten content. When the tungsten content increases to 25%, the melting point of the alloy is about 200℃ higher than that of pure molybdenum. Therefore, the corresponding alloy composition can be selected in the range of 2620-3410 °C according to the use temperature and the required melting point of the alloy. This advantage is also one of the advantages that molybdenum-tungsten alloys are widely used.

So tungsten-molybdenum alloy rods are mostly used as high-temperature components under high temperature conditions.

![]()

![]()

![]()

![]()

Do you want to know more about our products?

![]()