-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

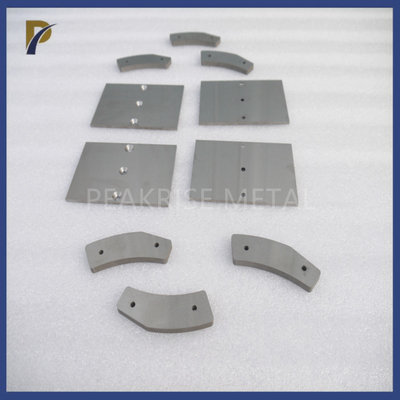

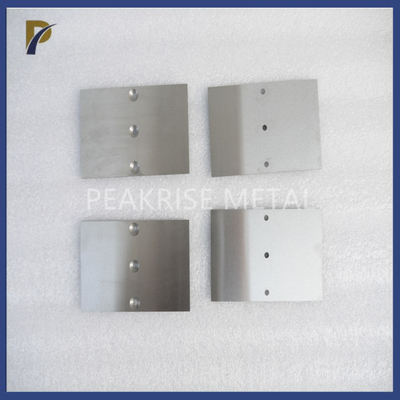

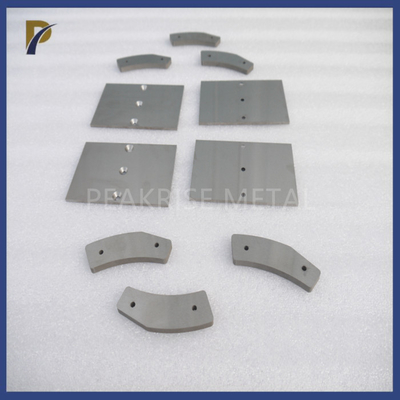

W70Cu Tungsten Copper Alloy Electronic Package Plate Sheet Copper Tungsten Electrode Material

| Name | WCu30 Tungsten Copper Alloy Electronic Package Sheet Metal Electrode | Material | W70Cu Alloy |

|---|---|---|---|

| Grade | W70Cu30 | Performance | Low Expansion Properties |

| Advantage | High Thermal Conductivity | Shape | Special-shaped Parts |

| Size | As Per Customer Drawing | ||

| Highlight | W70Cu Tungsten Copper Alloy,Tungsten Copper Alloy Sheet,tungsten copper plate |

||

W70Cu30 Tungsten Copper Alloy Electronic Package Sheet Metal Electrode

1. W70Cu30 Tungsten Copper Alloy Electronic Package Sheet Metal Electrode :

Tungsten copper encapsulation sheet and heat sink material have both the low expansion characteristics of tungsten and the high thermal conductivity of copper. Wide range of applications.

W70 tungsten copper encapsulation sheet, as the name suggests, is a material composed of 70% tungsten and 30% copper, of which 30±2% copper, and the impurity tungsten is 0.5%. Compared with W50 and W60 tungsten-copper alloys, the density and hardness of W70 tungsten-copper alloy are higher, and the density is about 13.80g/cm3, and the hardness is not lower than HB175. However, its electrical conductivity has decreased to about 42IACS%, its bending strength is 790, and its softening temperature is ≥900℃.

2. Performance comparison of different copper content :

| Grade | Density | Hardness | Resistance | Conductivity | Flexural strength |

| g/cm3≥ | HB Kgf/mm2≥ | µΩ.cm≤ | %≥ | Mpa≥ | |

| W50/Cu50 | 11.85 | 115 | 3.2 | 54 | -- |

| W55/Cu45 | 12.30 | 125 | 3.5 | 49 | -- |

| W60/Cu40 | 12.75 | 140 | 3.7 | 47 | -- |

| W65/Cu35 | 13.30 | 155 | 3.9 | 44 | -- |

| W70/Cu30 | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 16.75 | 260 | 6.5 | 27 | 1160 |

![]()

![]()

3.WCu30 Tungsten Copper Alloy Electronic Package Sheet Metal Electrode Manufacturing Techniques:

1). Powder metallurgy method: select fine tungsten and copper powder, refined by first-class infiltration and sintering process, can withstand nearly 2000 ℃ and high stress, has high melting point, high hardness, anti-burning and good anti-adhesion, galvanic corrosion The product has high surface finish, high precision and low loss. The alloy is prepared by powder metallurgy method, which has good electrical and thermal conductivity, good high temperature strength and certain plasticity.

2). Mechanical alloying method: a method of sintering the tungsten-copper powder that has been processed by high-energy ball milling and has achieved mechanical alloying between tungsten and copper. On the one hand, it can reduce the particle size of the metal powder and promote the densification process; on the other hand, it can also cause the metal powder to produce severe lattice distortion, high-density defects and nano-scale fine structure, making the thermodynamic and kinetic characteristics of the powder system. With off-equilibrium properties, such as higher surface energy and surface activity, greater sintering driving force and better sintering performance, etc.

Company profile:

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten and molybdenum non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tungsten alloy, molybdenum alloy and other more than 100 kinds of products.In 2010, with the surge in export sales of products in this industry, we began to focus on foreign trade export business,provide high-quality non-ferrous metal products for the international market.After years of development,at present, it has become a comprehensive non-ferrous metal production enterprise integrating manufacturing and processing, material research and development, product testing, and stock inventory.The development of nearly ten years reminds us that high-quality products and services are always our top priority,at the same time, we continue to expand into new fields and provide high-quality products and services for more domestic and global customers.Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customer.

Please click below button for learn more our products.

![]()