-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

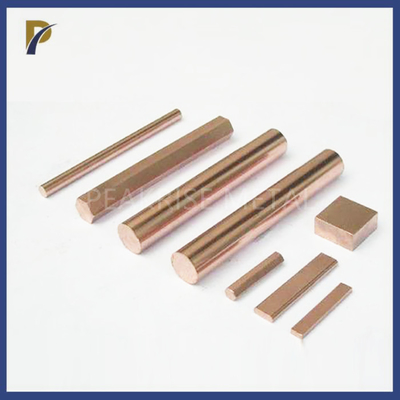

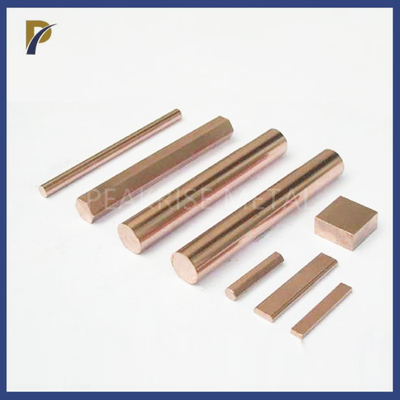

WCu20 Alloy Rod Copper Tungsten Alloy Bar Polished Surface Density 11.9 - 17.3g/Cm3

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Melting Point | 1450-1600℃ | Surface | Polished |

|---|---|---|---|

| Resistivity | ≤3.2~6.5μΩ·m | Flexural Strength | ≥1160~≥790MPa |

| Impact Strength | ≥30J | Coefficient Of Thermal Expansion | 6.3-9.7×10-6/K |

| Density | 11.9-17.3g/cm3 | Tensile Strength | ≥1000MPa |

| Highlight | WCu20 Alloy Rod,Polished Copper Tungsten Alloy Bar,17.3g/Cm3 Copper Tungsten Alloy Bar |

||

Product Description:

Tungsten copper alloy rod is a high-performance alloy material composed of two metal materials, tungsten and copper. Its production process is to mix tungsten and copper according to a certain ratio and then sinter at high temperature. Tungsten-copper alloy rod has high hardness and excellent electrical and thermal conductivity, as well as good corrosion resistance and wear resistance. Therefore, it is widely used in electronics, aviation, military and other fields under high temperature, high pressure, high strength and other harsh environments.

![]()

Other W and Mo products:

![]()

Features:

- Product Name: Tungsten Copper Alloy Rod

- Grade: WCu10, WCu20, WCu25, WCu30, WCu35, WCu40, WCu50, etc.

- Density: 11.9-17.3g/cm3

- Resistivity: ≤3.2-6.5μΩ·m

- Thermal Conductivity: 80-300W/mK

- Young's Modulus: 155-170GPa

- Copper Tungsten Alloy Sheet: High quality and good electrical performance.

- Cu10W90 Tungsten Copper Metal Alloy Electrode: Great welding performance.

- Tungsten Copper Heat Sink: Excellent heat resistance and thermal conductivity.

Applications:

Electronic device manufacturing

Machining

Aerospace

medical instruments

PRM specializes in the production of a variety of WCu20 alloy rods, WCu30 alloy plates, WCu25 alloy bars, WCu40 alloy tubes and WCu50 alloy strips. The products are uniform in size, accurate in specifications and reliable in quality. It can be used in the manufacture of various electrical components, mechanical parts, electrical connectors, aerospace, military and other fields, and can meet the requirements of different customers.

PRM provides customers with high-quality tungsten copper metal alloy electrodes, rods, plates, bars, tubes and strips. All of our products are designed to meet the highest quality standards and industry requirements. We also provide customized products according to customer requirements.

Technical Parameters:

| Name | Tungsten Copper Alloy Rod |

|---|---|

| Surface | Polished |

| Melting Point | 1450-1600℃ |

| Grade | WCu10 WCu20 WCu25 WCu30 WCu35 WCu40 WCu50 Etc. |

| Flexural Strength | ≥1160~≥790MPa |

| Thermal Conductivity | 80-300W/mK |

| Electrical Conductivity | ≥54~≥27%IACS |

| Resistivity | ≤3.2~6.5μΩ·m |

| Impact Strength | ≥30J |

| Hardness | ≥260~≥115HB |

| Keywords | Cu10W90 tungsten copper metal alloy electrode, copper tungsten alloy sheet, copper tungsten alloy sheet price, copper tungsten alloy sheet supplier |

Support and Services:

Tungsten Copper Alloy Rod technical support and services are available to customers. Our team of professionals can provide assistance with product selection, technical advice, and troubleshooting for customers. We also provide dedicated customer service, including product customization, to meet the individual needs of our customers.

Our technical support services include providing product guidance, installation instructions, and product maintenance advice. In addition, we offer a comprehensive after-sales service, including repairs and replacement parts, as well as a warranty program for Tungsten Copper Alloy products.

We endeavor to provide our customers with the highest quality of service and support for their Tungsten Copper Alloy products. If you have any questions or concerns, please feel free to contact us. We look forward to hearing from you.

Packing and Shipping:

Tungsten Copper Alloy Bar Packaging and Shipping:

The Tungsten Copper Alloy product should be packaged in a secure box or container to ensure that no damage occurs during shipment. The packaging should protect the product from any weather or other conditions that may cause corrosion. Additionally, the packaging should be properly labeled with the correct product information and handling instructions.

The Tungsten Copper Alloy product should also be shipped using a reputable and reliable shipping service. The product should be securely packaged to ensure that it arrives without any damage. The package should also be labeled correctly with the appropriate information so that it can be tracked and delivered correctly.

FAQ:

Tungsten Copper Alloy Bar