-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

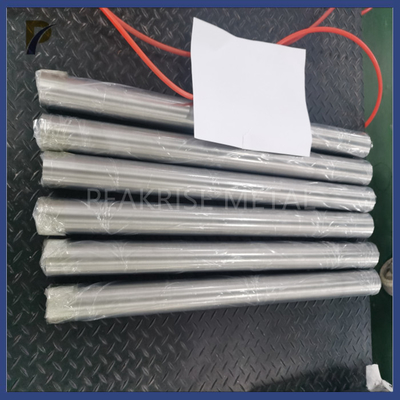

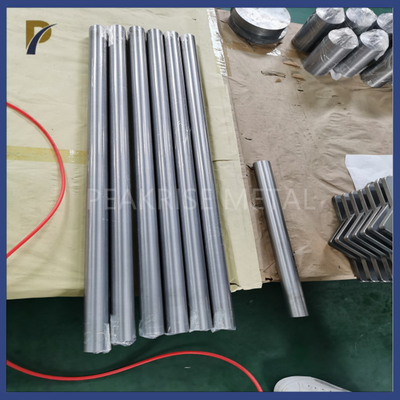

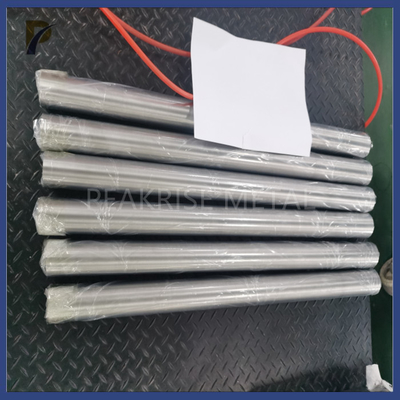

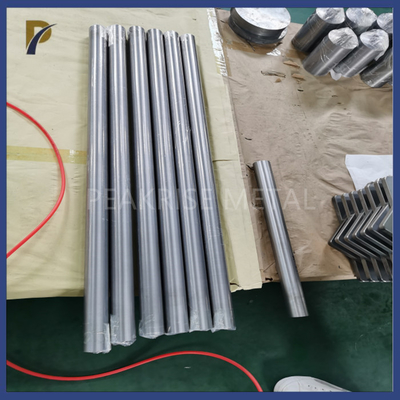

Polished Pure Molybdenum Rod Electrode For Glass Fiber Thermal Insulation Materials Molybdenum Electrodes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Molybdenum Rod Electrode For Glass Fiber | Material | Molybdenum |

|---|---|---|---|

| Type | Rod Electrode | Diameter | 4~120mm |

| Length | <1500mm | Surface | Polished |

| Purity | Min.99.95% | Density | 10.2g/cm3 |

| Highlight | Polished Pure Molybdenum Rod,Pure Molybdenum Rod,120mm Fiber Rod Electrode |

||

Molybdenum Rod Electrode For Glass Fiber

1. Description of Molybdenum Rod Electrode For Glass Fiber:

Molybdenum electrodes have good high temperature performance and corrosion resistance, good stability, high purity, and good electrical conductivity and thermal conductivity. They are often used as heating materials in daily glass, optical glass, thermal insulation materials, glass fiber and rare earth. Industry and other production fields. Molybdenum electrodes are mainly made by powder metallurgy and other processes. The performance of molybdenum electrodes plays an important role in the preparation of glass fiber glass. Because the electrode with high impurity content will affect the chroma and transparency of the glass. And the high-density molybdenum electrode is beneficial to prolong the service life of the furnace and the electrode, and at the same time, it is not easy to be corroded by the glass liquid, resulting in impurities that pollute the glass and the furnace. Therefore, to obtain high-quality glass fibers, molybdenum electrodes with high density, uniformity and low impurity content should be used as electrode materials.

![]()

![]()

2. Tolerance of Molybdenum Rod Electrode For Glass Fiber:

| Molybdenum Rod Electrode For Glass Fiber | |||||

| Dia [mm] |

tolerance [mm] |

length [mm] |

Surface | Straightness [per m] |

Approx weight [kg/m] |

| 4.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.128 |

| 10.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.801 |

| 20.00 | +/- 0.020 | 2000 | polished | <2.5 | 3.204 |

| 25.00 | +/- 0.040 | 2000 | polished | <2.5 | 5.007 |

| 30.00 | +/- 0.300 | 2000 | Polished | <1.5 | 7.210 |

| 40.00 | +/- 0.300 | 2000 | Polished | <1.5 | 12.818 |

| 50.00 | +/- 0.400 | 2000 | Polished | <1.5 | 20.654 |

| 60.00 | +/- 0.400 | 2000 | Polished | <1.5 | 28.840 |

| 63.50 | +/- 0.400 | 2000 | Polished | <1.5 | 32.303 |

| 70.00 | +/- 0.400 | 2000 | Polished | <1.5 | 39.254 |

| 80.00 | +/- 1.000 | 2000 | Polished | <2.5 | 51.271 |

| 90.00 | +/- 1.000 | 2000 | Polished | <2.5 | 64.890 |

| 100.00 | +/- 1.000 | 2000 | Polished | <2.5 | 80.111 |

| 120.00 | +/- 2.000 | 2000 | Polished | <2.5 | 115.359 |

3. Main craft of Molybdenum Rod Electrode For Glass Fiber:

Molybdenum powder----Pressing----Sintering----Forging hammer----Processing----Inspection----Finished product----Packing----Delivery

4. Actual Chemical testing of Molybdenum Rod Electrode For Glass Fiber:

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Ca | P | Cu | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.0006 | 0.0006 | 0.001 | 0.0006 | 0.003 | 0.0006 | 0.003 | 0.0006 | 0.001 | 0.0006 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | Sb | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.001 | 0.005 | 0.0006 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||