-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

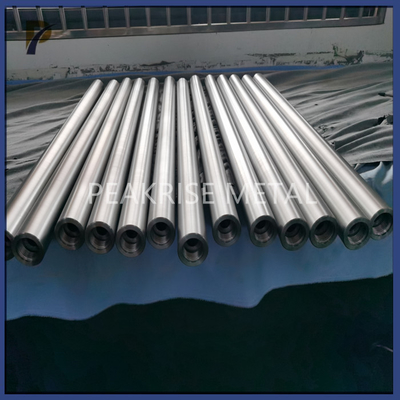

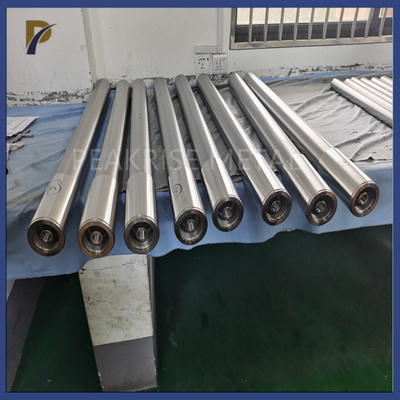

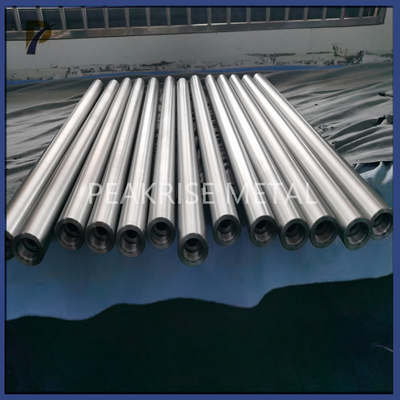

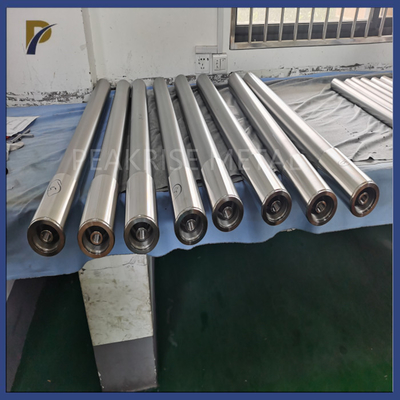

Glass Electric Boosting Pure Molybdenum Electrodes 1300mm Length

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Glass Electric Boosting Molybdenum Electrodes | Material | Pure Molybdenum |

|---|---|---|---|

| Purity | 99.95% | Density | 10.2g/cm3 |

| Diameter | 25~80mm | Length | ≤1300 Mm |

| Surface | Polished | Standard | ASTM B387 |

| Highlight | Glass Electric Boosting Molybdenum Electrodes,1300mm Electrode Rod,Heating System Pure Molybdenum Electrodes |

||

Glass Electric Boosting Molybdenum Electrodes

1. Product descriptions of Glass Electric Boosting Moybdenum Electrode:

What Are Molybdenum Electrodes?

Molybdenum electrodes are created via balancing pressing, forging, rolling, planing, and milling after being sinterized in a medium frequency furnace. It serves as a piece of the glass fiber kiln's electro-heating system.

Molybdenum is the primary material in the molybdenum electrode and is produced using powder metallurgy. To ensure the quality of the glass and the longevity of the electrode, the widely used molybdenum electrode has a density more than 10.15g/cm3 and contains 99.95% of the components. Molybdenum electrodes are frequently employed, and their sizes range from 20 to 152.4 mm in diameter and up to 1500 mm in length. The present molybdenum electrode may effectively minimize environmental pollution by substituting for the original heavy oil and gas energy and improve the quality of glass.

Mo electrodes of PRM metal

| Electrode type | Diameter,mm | Tolerances,mm | Roughness Ra | Length tolerances, mm |

|---|---|---|---|---|

| Turned | From 25 to 30 | ± 0.26 | 2.5 | <± 6.35 |

| > 35 to 50 | ± 0.31 | 2.5 | ||

| > 50 to 80 | ± 0.37 | 2.5 | ||

| Grinded | From 25 and more | ± 0.08 | 1.25 |

![]()

![]()

Based on the client's desire, electrode lengths and diameters greater than 80 mm are established.

Guaranteed chemical composition of Mo99.95%-Mo electrodes.

| Grade | Mo,% | Impurities, ppm, maximum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O | N | C | Fe | Al | Ni | Si | Mg | Na | K | Ca | W | ||

| M99.95 | >99.95 | 70 | 50 | 100 | 100 | 30 | 50 | 50 | 20 | 30 | 80 | 40 | 130 |

| ∑Fe, Si, Ni, Al, W, Mg, Na, K, Ca <400 | |||||||||||||

| Total content of metallic impurities <500 | |||||||||||||

Sample chemical composition of Mo99.95-Mo electrodes of various diameters.