-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

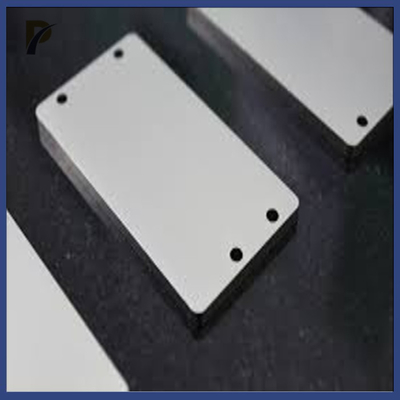

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

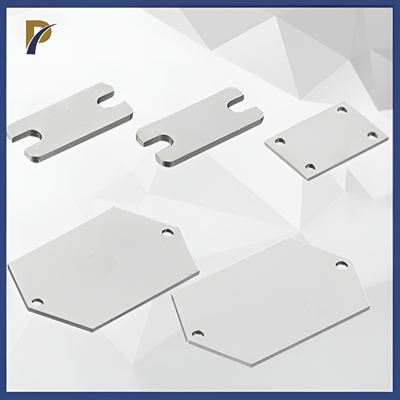

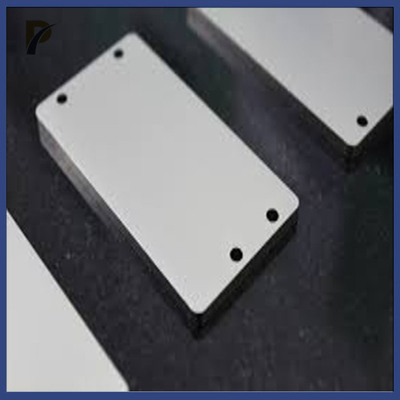

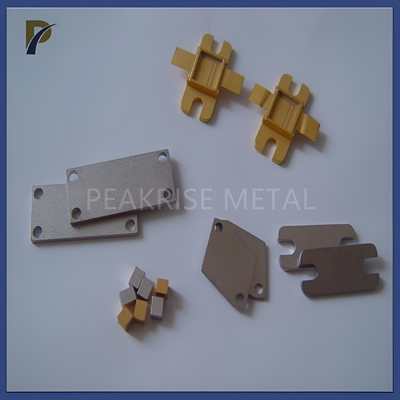

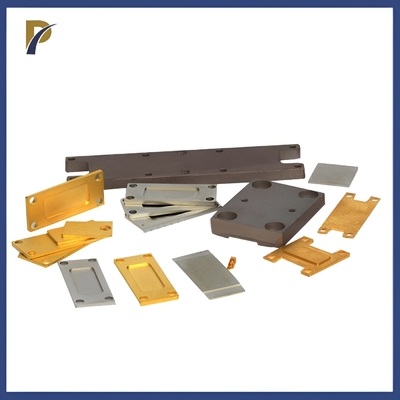

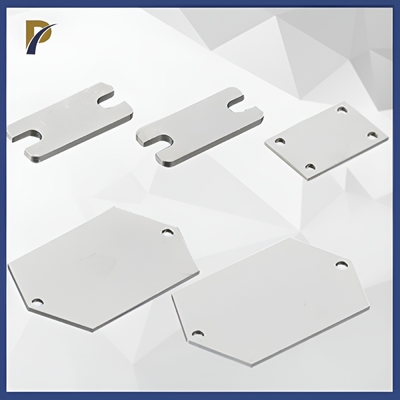

Heat Sink Molybdenum Copper Alloy For MoCu Substrates In Laser Microwave Ceramic Metal

| Name | Molybdenum-Copper Alloy Heat Sink For MoCu Substrates In Laser Microwave Ceramic-Metal Packages | Material | Molybdenum Copper Alloy |

|---|---|---|---|

| Grade | MoCu30,MoCu40,MoCu50,MuCu60,MoCu70,MoCu80,MoCu90 | Size | As Per Customer's Drawing |

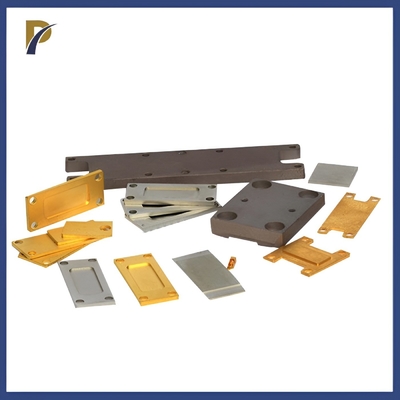

| Surface | Bright | Plating | Nickel Or Silver |

| Package | Vacuum Package | Export Port | Any Port In China |

| Highlight | MoCu40 Molybdenum Copper Alloy,Molybdenum Copper Alloy For MoCu Substrates,Ceramic Metal Molybdenum Copper Alloy |

||

Molybdenum-Copper Alloy Heat Sink For MoCu Substrates In Laser Microwave Ceramic-Metal Packages

1. Information Of MoCu Alloy Heat Sink For MoCu Substrates:

Molybdenum-copper heat sink is a high-performance heat dissipation material, which is processed by composite processing of molybdenum-based materials and copper-based materials. Its main features are high thermal conductivity, good thermal expansion and excellent corrosion resistance.

2. Size Of MoCu Alloy Heat Sink For MoCu Substrates:

The size of molybdenum copper heat sink can be customized according to customer requirements. Generally speaking, its thickness is 0.3~5mm, and its length and width can reach more than 200mm.

![]()

![]()

3.Performance Of MoCu Alloy Heat Sink For MoCu Substrates:

| Grade |

Mo content Wt% |

Density g/cm3 |

Thermal conductivity W/m-K |

Thermal expansion coefficient ×10-6 |

Conductivity IACA% |

Hardness HV |

| MoCu50 | 50±2 | 9.54 | 250-268 | 11.3 | >55 | 140 |

| MoCu40 | 60±2 | 9.62 | 216-248 | 10.1 | >55 | 156 |

| MoCu30 | 70±2 | 9.72 | 170-205 | 8.4 | >45 | 172 |

| MoCu20 | 80±2 | 9.85 | 160-190 | 7.3 | >40 | 225 |

4. Advantages Of MoCu Alloy Heat Sink For MoCu Substrates:

1). High thermal conductivity: Molybdenum copper heat sink has excellent thermal conductivity, and its thermal conductivity can reach more than 160W/mK, which is more than 2.5 times that of copper materials, so it is very suitable for heat dissipation of high-power electronic components.

2). Excellent corrosion resistance: molybdenum copper heat sink not only has excellent thermal conductivity, but also has high corrosion resistance, and is not easily corroded by corrosive media such as humid environment, acid, alkali, etc. It can also maintain its stable performance.

3). Good thermal expansion: Since the linear expansion coefficients of molybdenum and copper are far different, compound processing is required when preparing molybdenum-copper heat sinks. The thermal expansion performance and thermal stress distribution are uniform, which can effectively prevent heat cracks from occurring in the heat sink.

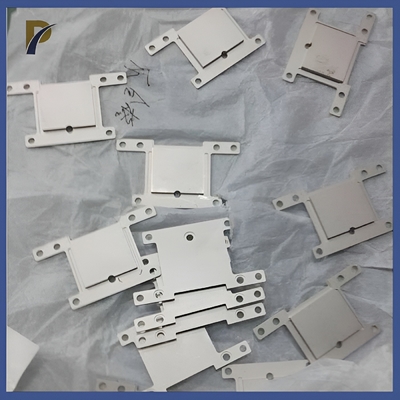

5. Production process Of MoCu Alloy Heat Sink For MoCu Substrates:

The production process for preparing molybdenum-copper heat sinks generally includes steps such as powder metallurgy, hot isostatic pressing, and sintering. The specific process is as follows:

1). Mix molybdenum powder and copper powder in proportion to make mixed powder;

2). Put the mixed powder in the shaper, and use high temperature and high pressure for hot isostatic pressing;

3). After hot isostatic pressing, sintering is carried out to weld molybdenum and copper;

4). After sintering, finish machining and cutting to make the required size and shape.

6.Application scope Of MoCu Alloy Heat Sink For MoCu Substrates:

Molybdenum-copper heat sinks are widely used in the heat dissipation of high-power electronic components and devices. For example, power devices such as IGBTs, FETs, and ultra-fast diodes all require heat sinks for heat dissipation. In addition, molybdenum copper heat sinks are also widely used in aerospace, national defense, communication equipment, metal packaging and other fields.

In a word, molybdenum copper heat sink is an excellent heat dissipation material with high thermal conductivity, excellent corrosion resistance and good thermal expansion performance, and is suitable for heat dissipation of various high-power electronic components and devices.

About us:

Shaanxi Peakrise Metal manufactures W/Cu, Mo/Cu, Cu/Mo/Cu, Cu/Mo70Cu/Cu high-performance electronic packaging materials, WNiFe, WNiCu and their alloys are recognized leaders in the deep processing industry. We also have a dedicated production department and R&D department for various high-tech vacuum furnaces. Based on the goal of "sincerity, win-win, credit first", Peakrisemetal has built an advanced technological innovation platform. Our products are widely used in microwave devices, laser power boards, communications, fiberglass, military industry, glass industry, vacuum furnaces, vacuum coating, clean energy, LED lighting, medical technology, semiconductors, touch panels, solar energy and electronic equipment.

Peakrisemetal has established sales channels and technical partnerships in North America, Europe and the Middle East. The products have been exported to more than 50 countries and regions such as the United States, France, Germany, Italy, Japan, South Korea and Taiwan, and have been accepted by many well-known domestic and foreign enterprises.