-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

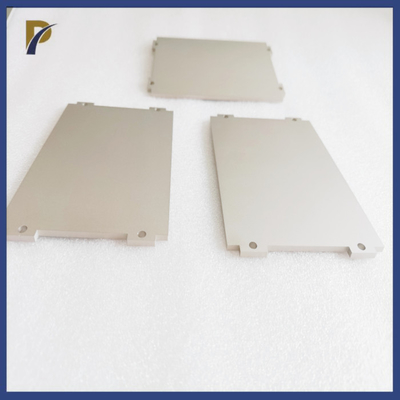

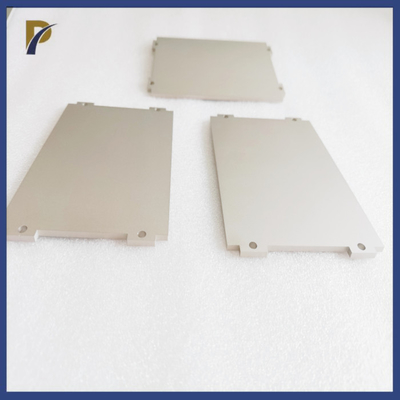

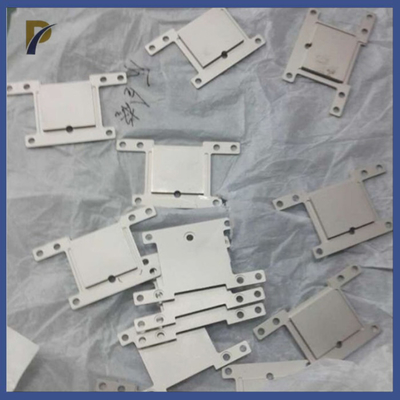

MoCu20 MoCu30 MoCu50 MoCu40 Copper Molybdenum Alloy For Heat Sink Fins 160 - 180 W/MK

| Name | Molybdenum Copper Alloy | Corrosion Resistance | Excellent |

|---|---|---|---|

| Composition | Molybdenum Copper Alloy | MOQ | 5pcs |

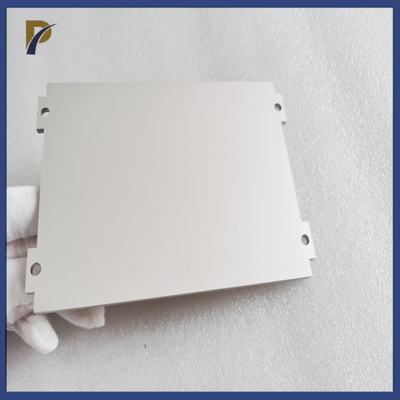

| Plating | Nickel Or Silver | Density | 9.64~9.98g/cm3 |

| Thermal Conductivity | 160~280 W/M·K | Conductivity | 0.034~0.05 μΩm |

| Highlight | MoCu40 Copper Molybdenum Alloy,Heat Sink Fins Copper Molybdenum Alloy,Molybdenum Copper Heat Sink Sheet |

||

Product Description:

Molybdenum copper is a composite material of molybdenum and copper, its performance is similar to that of tungsten copper, and it also has adjustable thermal expansion coefficient and thermal conductivity. Compared with tungsten copper, the disadvantage of molybdenum copper is that the thermal expansion coefficient and thermal conductivity are relatively slightly worse than tungsten copper, but the advantage of molybdenum copper is obvious, that is, the density is much smaller than tungsten copper, and it is precisely because of this One point makes molybdenum copper more suitable for aerospace, microelectronic packaging, communication and other fields.

| Grade |

Mo content Wt% |

Density g/cm3 |

Thermal expansion coefficient ×10-6 CTE(20℃) |

Thermal Conductivity W/(M·K) |

ConductivityμΩm |

Hardness HV |

| 85MoCu | 85±2% | 9.98 | 6.8 | 160~180 | 0.05 | 210 |

| 80MoCu | 80±2% | 9.91 | 7.7 | 170~190 | 0.046 | 190 |

| 70MoCu | 70±2% | 9.77 | 9.1 | 200~250 | 0.04 | 180 |

| 65MoCu | 65±2% | 9.70 | 9.7 | 210~270 | 0.038 | 176 |

| 60MoCu | 60±2% | 9.64 | 10.3 | 220~280 | 0.034 | 170 |

![]()

Characteristic:

1. The molybdenum-copper alloy used for electronic packaging (heat sink), similar to tungsten-copper alloy, also has adjustable composition, so it has adjustable thermal conductivity and thermal expansion coefficient.

2. Compared with tungsten-copper alloy, molybdenum-copper alloy has a lower density, but a larger coefficient of thermal expansion.

3. Power electronic devices and circuits will generate a lot of heat during operation. The heat sink material helps to dissipate the heat of the chip, transfer it to other media, and maintain the stable operation of the chip.

4. It has a thermal expansion coefficient and high thermal conductivity that match different substrates, excellent high temperature stability and uniformity, and excellent processing performance;

5. Molybdenum-copper alloy is an alloy material composed of two insoluble metals molybdenum and copper. It has the characteristics of both molybdenum and copper. It has high thermal conductivity, low thermal expansion coefficient, non-magnetic, low gas content and good vacuum Performance, good machinability and special high temperature performance and other characteristics.

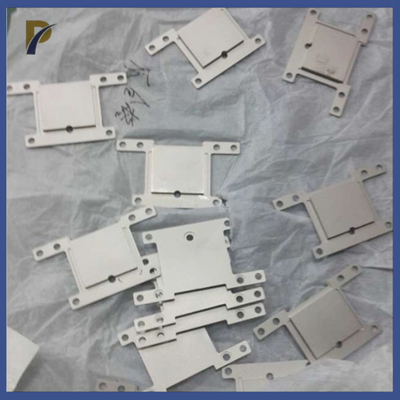

6. Compared with tungsten copper, molybdenum copper alloy has a lower density and can be stamped and processed, which is suitable for super large batches.

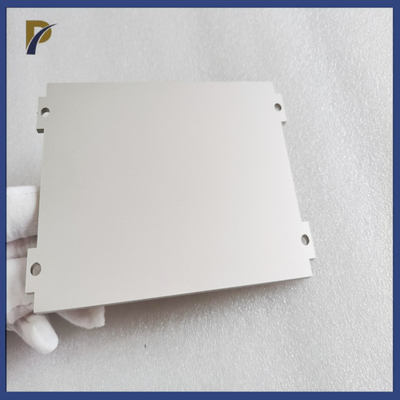

Advantages of our company's molybdenum copper

1. Molybdenum copper does not add any adhesive, and has good thermal conductivity;

2. There is no copper pool in the metallographic phase of molybdenum copper, and the performance is stable;

3. The copper content control of molybdenum copper is very stable, and the thermal expansion coefficient and thermal conductivity are very stable;

4. The production cost of the heat sink produced by the stamping process is lower;

5. The relative density is ≥99%, the porosity is low, the product has good air tightness, and the leak detection test of the helium mass spectrometer ≤5×10-9Pa·m3/S can be completely passed;

6. Better electroplating quality and good thermal shock resistance.

![]()

Packing and Shipping:

Molybdenum copper alloy is typically packaged in a sealed, clean, dry, and rust-free environment. The packaging may vary depending on the size of the product being shipped and the type of alloy. For instance, small molybdenum copper alloy components may be packaged in individual boxes or containers, while larger components may be packaged in wooden crates or pallets.

Shipping of molybdenum copper alloy is primarily done through ground transportation. To ensure safe delivery, the alloy should be packaged in sturdy containers and wrapped with protective material to prevent damage during transit. The containers must be properly labeled and clearly marked with the appropriate shipping information, including the recipient’s address and contact information. Depending on the size of the shipment, additional protective measures, such as shrink-wrapping or strapping, may be required.

FAQ:

Q: What is the Brand Name of Molybdenum Copper Alloy?

A: The brand name of Molybdenum Copper Alloy is PRM.

Q: Where is Molybdenum Copper Alloy made?

A: Molybdenum Copper Alloy is made in China.

Q: What is the certification for Molybdenum Copper Alloy?

A: Molybdenum Copper Alloy is certified with ISO9001.

Q: What is the minimum order quantity for Molybdenum Copper Alloy?

A: The minimum order quantity for Molybdenum Copper Alloy is 5pcs.