-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

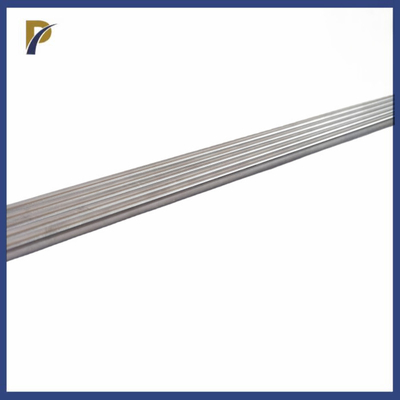

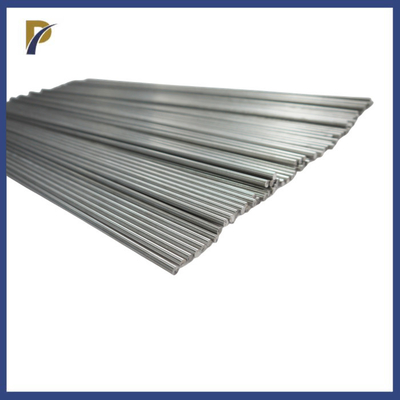

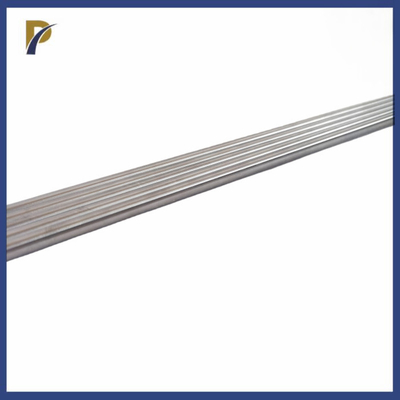

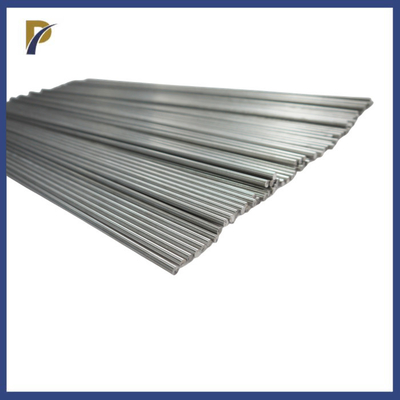

ASTM F67 Medical Titanium Rod Gr1ELI TA1ELI Titanium rod bar

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | ASTM F67 Medical Titanium Rod Gr1ELI TA1ELI Titanium Rod Bar | Material | Medical Titanium |

|---|---|---|---|

| Grade | Gr1ELI TA1ELI | Shape | Rod Bar |

| Purity | ≥99.7% | Density | 4.51g/cm3 |

| Standard | ASTM F67 | Surface | Polished |

| Highlight | Gr1ELI Medical Titanium Rod,TA1ELI Medical Titanium Rod,ASTM F67 Medical Titanium Rod |

||

Medical Titanium Rod:

| Specifications: | Rolling ¢8.0---40mm× L; Forging ¢40---150mm×L |

| Metallurgical structure: | Pure titanium grain size is not less than grade 5, TC4 titanium alloy meets A1-A9. |

| Surface: | Black leather surface, polished surface, polished surface (H11, H9, H8) |

| Performance of medical titanium rods | reference implementation standards: GB/T13810-2007, ASTM F67/F136 |

Room temperature properties of medical titanium rods GB/T13810-2007:

|

Grade

|

Status

|

Diameter or side length

|

Tensile strengthσb

|

Yield Strengthσ0.2

|

Elongation after fracture

|

Rate of reduction in area

|

|

mm

|

MPa

|

MPa

|

A%

|

Z%

|

||

|

TA1ELI

|

M

|

>7~90

|

≥200

|

≥140

|

≥30

|

≥30

|

|

TA1

|

M

|

≥240

|

≥170

|

≥24

|

≥30

|

|

|

TA2

|

M

|

≥400

|

≥275

|

≥20

|

≥30

|

|

|

TA3

|

M

|

≥500

|

≥380

|

≥18

|

≥30

|

|

|

TA4

|

M

|

≥580

|

≥485

|

≥15

|

≥25

|

|

|

TC4

|

M

|

>7~50

|

≥930

|

≥860

|

≥10

|

≥25

|

|

M

|

>50~90

|

≥895

|

≥830

|

≥10

|

≥25

|

|

|

TC4ELI

|

M

|

>7~45

|

≥860

|

≥795

|

≥10

|

≥25

|

|

M

|

>45~65

|

≥825

|

≥760

|

≥8

|

≥20

|

|

|

M

|

>65~90

|

≥825

|

≥760

|

≥8

|

≥15

|

|

|

TC20

|

M

|

>7~100

|

≥900

|

≥800

|

≥10

|

≥25

|

|

Note: For titanium bars with a diameter greater than 75 mm, take the bar-shaped specimen.

|

||||||

The mechanical properties of medical titanium rods comply with GB/T13810-2007 and ASTM F67/F136.

Using titanium rods to make artificial bones, cells can regenerate on them and bones can grow. Titanium has good affinity with human bones, epithelium, and artificial tissue. In order to improve the surface quality of implants connected to human bones, applying a bioceramic layer to the roughened surface is also a more effective method.