-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

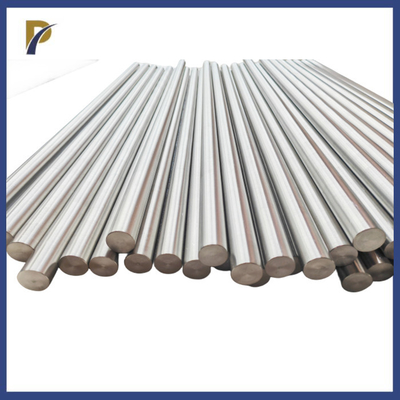

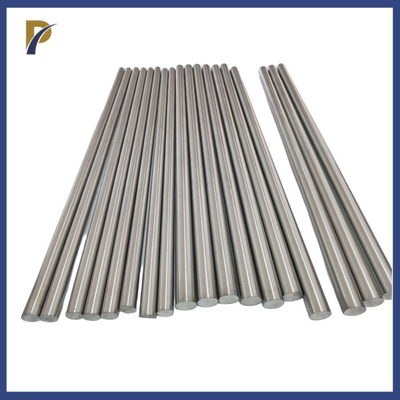

RO5200 Tantalum Bar Tantalum Rod For Chemical Processing Equipment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | RO5200 Tantalum Bar Tantalum Rod For Chemical Processing Equipment | Purity | 99.95% |

|---|---|---|---|

| Grade | RO5200 RO5400 RO5252,RO5255 Etc. | Melting Pointt | 2996°C |

| Diameter | ¢3~¢120mm | Standard | ASTM B365 |

| Density | 16.67g/cm3 | Type | Manufacturer |

| Highlight | Chemical Processing Equipment Tantalum Rod,RO5200 Tantalum Rod,Tantalum Bar Tantalum Rod |

||

Tantalum rods are highly prized in chemical processing equipment due to their exceptional resistance to corrosion, high melting point, and overall durability. Tantalum is particularly effective in environments where strong acids, alkalis, and other reactive chemicals are present, making it a key material in the construction of various chemical processing components.

Key Features of Tantalum Rods for Chemical Processing:

-

Exceptional Corrosion Resistance: Tantalum is nearly immune to attack from most acids, including hydrochloric acid, sulfuric acid, nitric acid, and even aqua regia. This property makes tantalum rods ideal for use in equipment handling highly corrosive chemicals.

-

High Melting Point: With a melting point of approximately 2996°C (5425°F), tantalum can withstand extremely high temperatures, making it suitable for high-temperature chemical reactions.

-

Chemical Inertness: Tantalum is chemically inert in most environments, meaning it doesn’t react with chemicals, even in extreme conditions. This ensures a longer service life for equipment made from or protected by tantalum.

-

Thermal Stability: Tantalum maintains its mechanical and chemical properties even at elevated temperatures, which is essential for high-temperature chemical processes.

-

Non-Toxic and Safe: Tantalum does not leach or contaminate materials being processed, making it safe for use in chemical processing equipment where product purity is critical.

| Grade | Main elements | Impurity content less than % | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Remain | —— | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 |

| Ta2 | Remain | —— | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.03 | 0.01 | 0.0015 | 0.01 |

| TaNb3 | Remain | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.03 | 0.01 | 0.0015 | 0.01 |

| TaNb20 | Remain | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.03 | 0.01 | 0.0015 | 0.01 |

| Ta2.5W | Remain | 0.005 | 0.005 | 0.002 | 3 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 | |

| Ta10W | Remain | 0.005 | 0.005 | 0.002 | 11 | 0.01 | 0.002 | 0.04 | 0.02 | 0.01 | 0.0015 | 0.01 | |

Applications of Tantalum Rods in Chemical Processing Equipment:

-

Heat Exchangers: Tantalum rods are used in the construction of heat exchangers that handle highly corrosive fluids, as tantalum can endure both heat and chemical exposure without degrading.

-

Reactor Vessels: Tantalum rods are utilized in reactors that process aggressive chemicals under high pressure and temperature, protecting the reactor from corrosion and extending its lifespan.

-

Piping Systems: Tantalum rods can be fashioned into fittings, flanges, and other parts of piping systems that transport corrosive liquids and gases in chemical plants.

-

Evaporators: Tantalum rods are used in evaporators to prevent chemical attacks from concentrated acids, ensuring that the equipment can withstand prolonged exposure without corroding or failing.

-

Liners for Chemical Vessels: Tantalum rods are used to make liners for steel vessels to provide an additional layer of corrosion resistance. This is particularly valuable in acid or chloride processing industries.

-

Thermowells and Sensors: In environments where temperature measurement and control are necessary, tantalum rods are used in thermowells and sensors because of their resistance to corrosion, even at elevated temperatures.

-

Anodes for Electrochemical Processing: Tantalum is often used as an anode material in electrochemical processing equipment due to its high stability and conductivity, which is vital in processes such as electroplating and electrolysis.

Advantages of Tantalum Rods for Chemical Processing:

- Long Service Life: Equipment made from or protected by tantalum rods lasts significantly longer than components made from other materials in highly corrosive environments, reducing downtime and maintenance costs.

- High Efficiency: Tantalum allows for more efficient chemical processing, as it can operate in extreme conditions that would otherwise cause rapid degradation in other materials.

- Enhanced Safety: The non-reactive nature of tantalum reduces the risk of dangerous chemical reactions, leaks, or contamination in processing environments.

Industries Benefiting from Tantalum Rods:

- Chemical and Petrochemical: Equipment used in the production and processing of chemicals such as hydrochloric acid, sulfuric acid, and chlorine.

- Pharmaceutical: Used in equipment where chemical purity and resistance to contamination are critical.

- Metallurgical Processing: Tantalum rods are used in the production of highly corrosive materials like titanium, zirconium, and other metals.

- Mining and Extraction: In the processing of materials involving harsh chemicals, tantalum’s corrosion resistance ensures durability and performance.

Tantalum rods provide crucial protection and functionality in chemical processing equipment, ensuring efficiency and longevity in environments where other materials would rapidly degrade.

Would you like more detailed information on its specific uses, properties, or purchasing options?

Pls contact with us ,send exact size and quantity ,we will quote best price for you.

![]()