-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Stamping Evaporation Tungsten Boat For Resistive Evaporation Source Vacuum Evaporation Coating Boat

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Evaporation Tungsten Boat Used For Resistive Evaporation Source | Material | Pure Tungsten |

|---|---|---|---|

| Purity | Min.99.95% | Density | 19.3g/cm3 |

| Craft | Stamping | Applictaion | Evaporation Coating Industry |

| MOQ | 1pc | Export Port | Any Port In China |

| Highlight | Evaporation Tungsten Boat,Stamping Tungsten Boat |

||

Resistive Evaporation Source Using Tungsten Evaporation Boat

1. Description of Resistive Evaporation Source's Tungsten Boat for Evaporation:

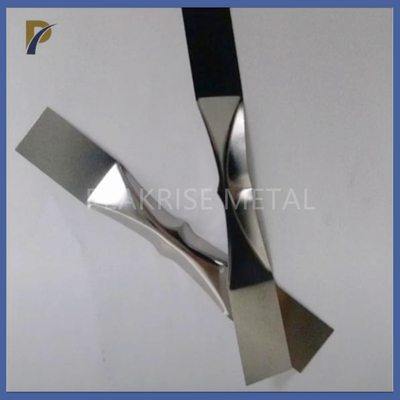

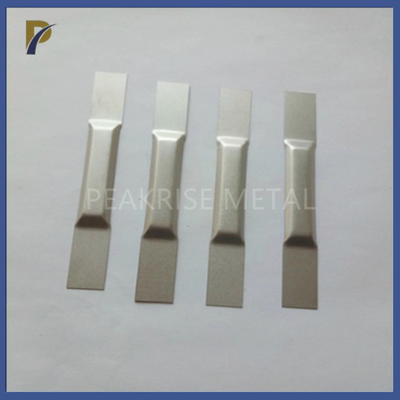

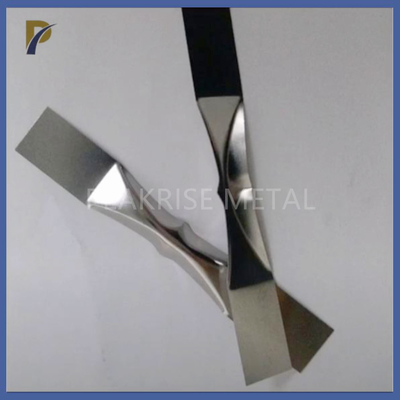

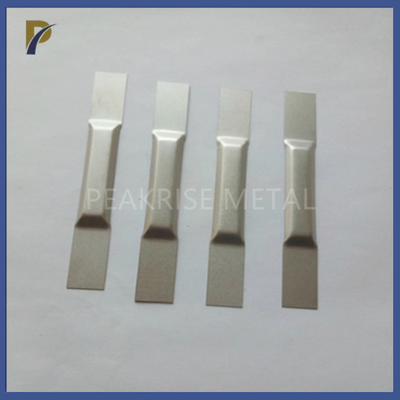

One of the varieties of tungsten boats is coated or evaporated, and tungsten boats are frequently employed in the evaporation coating business. In the vacuum evaporation coating business, evaporated tungsten boats are frequently employed as resistive evaporation sources due to their high melting point, low saturated vapor pressure, and stable chemical characteristics. In vacuum coating equipment, tungsten boats of the evaporation type are a necessary component, and the coating's quality depends on the boat used. The melting point of the coating material cannot be higher than the melting point of the tungsten boat when the evaporation type tungsten boat evaporates it; otherwise, there is no way to proceed.

![]()

![]()

2. Type of Evaporation Resistive Evaporation Source Tungsten Boat:

|

Type

|

Thickness( mm)

|

Width( mm)

|

Length( mm)

|

Manufacturer

|

|

#207

|

0.2

|

7

|

100

|

Shaanxi Peakrise Metal CO.,Ltd

|

|

#215

|

0.2

|

15

|

100

|

|

|

#308

|

0.3

|

8

|

100

|

|

|

#310

|

0.3

|

10

|

100

|

|

|

#315

|

0.3

|

15

|

100

|

|

|

#413

|

0.4

|

13

|

50

|

|

|

#525

|

0.5

|

25

|

78

|

3. Evaporation Production Process For Resistive Evaporation Source, A Tungsten Boat:

The process of evaporation involves vaporizing or sublimating the substance that will be transformed into a film in a vacuum, causing it to precipitate on the surface of the substrate or workpiece. The vapor-deposited tungsten boat is prepared in a manner akin to the stamped tungsten boat, with the exception that the former features steam holes on the boat cover.

4. Application of the Tungsten Boat Used As a Resistive Evaporation Source for Evaporation:

In resistance evaporation sources, tungsten boats of the evaporation type are also frequently utilized. The tungsten boat is initially placed in between the two electrodes, materials are then placed in its middle, and finally, the electrodes are gradually energized. The heat produced by the high melting point tungsten boat will be transferred to the coating material by the current. The coating substance will sublime or evaporate when the tungsten boat's temperature exceeds the coating's melting point.

Do you want to know more about our products?

![]()