-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

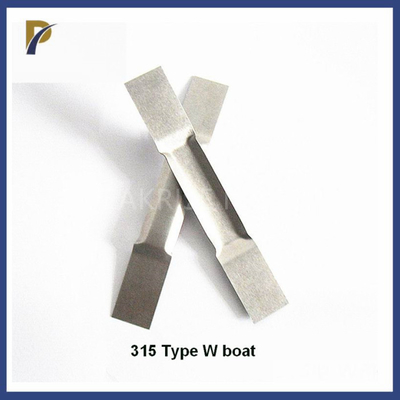

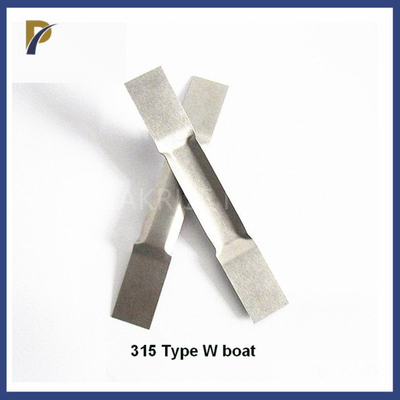

#510 Thermal Tungsten Evaporation Boat ASTM B 770 Standard Evaporation Material Tungsten Boats Stamping Tungsten Boat

| Name | #510 Evaporation Boat Evaporation Tungsten Coat | Material | Pure Tungsten |

|---|---|---|---|

| Purity | Min.99.95% | Density | 19.3g/cm3 |

| Surface | Bright | Craft | Stamping |

| Standard | ASTM B 770 | MOQ | 1pc |

| Highlight | 510 Tungsten Evaporation Boat,Bright Tungsten Evaporation Boat,thermal evaporation boat |

||

#510 Evaporation Boat Evaporation Tungsten Coat

1. Information about #510 Evaporation Boat Tungsten Coat:

Tungsten boats can also be called evaporated tungsten boats or coated tungsten boats. They are formed by high temperature stamping of tungsten sheets. There are punching boats, folding boats and other types. They are widely used in the vacuum coating industry and the sintering furnace sintering or vacuum annealing boat industry.

2. Common #510 size Evaporation Tungsten Coat Evaporation Boat:

| Type | Length (mm) | Width(mm) | Thickness(mm) | Groove depth(mm) |

| #210 | 100 | 10 | 0.2 | 2.4~2.5 |

| #310 | 100 | 10 | 0.3 | 2.4~2.5 |

| #315 | 100 | 15 | 0.3 | 2.4~2.5 |

| #510 | 100 | 25 | 0.5 | 2.1 |

We can accept all kinds of heterosexual boat customization according to customer's drawing.

![]()

![]()

3.Classification of Evaporation Boat Evaporation Tungsten Coat:

1). Flat groove boat: ideal for materials with great wet wettability.

2). V-shaped groove boat: suitable for materials with less wettability.

3). Oval grooved boat: suitable for materials in molten state.

4). Spherical groove boat: suitable for expensive materials such as gold and silver.

5). Narrow slot boat: This design prevents the evaporation material from sticking to the filament clip.

6). Evaporating aluminum boat: A layer of aluminum oxide is plated on the surface of the boat body to help the evaporation boat resist the molten material with strong corrosiveness.

7). Compared with 310, 510 is thicker and less prone to deformation or bending, and is more suitable for materials that are difficult to evaporate.

8). The tungsten boat is mainly used for evaporation in the vacuum evaporation coating process: powders, particles, high-priced metals, high-temperature refractory metal powders, and can also be used to evaporate indium wire, tin wire, aluminum wire, copper wire, etc.