-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

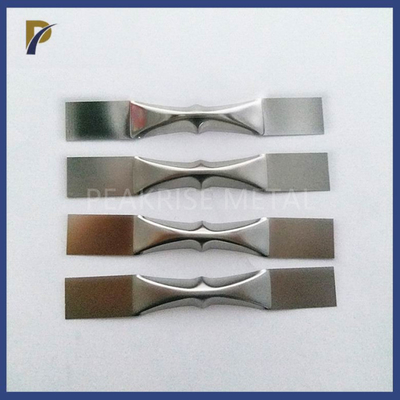

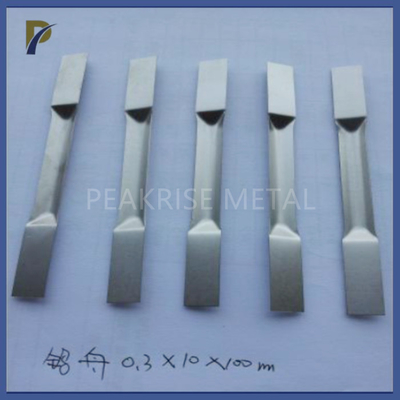

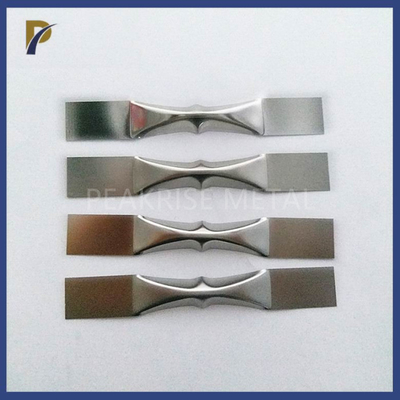

Pure Tungsten Boat Thermal Evaporation For Vacuum Industry Tungsten Coating Boats Stamping Tungsten Boat

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Tungsten Boat For Vacuum Industry | Material | Pure Tungsten |

|---|---|---|---|

| Purity | Min99.95% | Desnity | 19.3g/cm3 |

| Type | Stamping Boat,Riveting Boat, Welding Boat, Folding Boat | Surface | Bright,Alkaline Washing |

| Highlight | Pure Tungsten Boat,Industry Tungsten Boat,tungsten boat thermal evaporation |

||

Tungsten Boat For Vacuum Industry

1. Description of Tungsten Boat For Vacuum Industry:

Other names for tungsten boats include coated tungsten boats and evaporated tungsten boats. They are created by stamping sheets of tungsten metal at high temperatures. There are many different kinds of boats, including folding boats. They are extensively employed in the vacuum coating and vacuum annealing of boats industries, as well as in sintering furnaces.

![]()

![]()

2. For The Vacuum Industry, What Sort Of Tungsten Boat:

Stamped Tungsten Boat

The tungsten boat is stamped using standard or specialized stamping equipment to apply pressure to the tungsten plate and create plastic deformation in the stamping die, resulting in the final tungsten boat size. The primary method of processing the stamped tungsten boat is hot stamping. Because stamping often does not produce chips or trash, stamped tungsten boats can increase their stiffness while using fewer tungsten plates and paying less overall. As a result, stamped tungsten boats will be reasonably priced.

Foldable tungsten boat

The folding tungsten boat requires a fair amount of preparation. The tungsten plate is folded and processed in order to finally take on the shape of a boat by continuously folding and forging the two ends of the plate. The folded tungsten boat has strong permeability. This form of tungsten boat contains a number of attachments, including a cover and body, in contrast to other types.

Welded tungsten boat

The term heated tungsten boat also refers to welded tungsten boat. Five tungsten plates are heated to a high temperature and then under pressure to allow the joints to melt together. After welding, the plates are allowed to cool down to form the shape of a boat. However, welding tungsten boats takes a lot of time and cannot be done all at once. Fusion welding and brazing are the two main methods used to weld pure tungsten. This kind of tungsten boat is quite enormous in size.

Riveted Tungsten Boat

The process of riveting involves joining two or more metals together, and tungsten rivets are typically used to do it. As a result, the joint strength of the riveted tungsten boat is rather steady and trustworthy, and the tightness of the joint can be increased. In general, the rivet tungsten boat is used to join two tungsten plates of equal thickness by drilling holes in their components, inserting rivets, and then using a rivet gun to secure the rivets.Additionally, it can be joined together to create a tungsten boat with a more intricate construction. The preparation of rivet-type tungsten boats requires the use of rivets. As a result, the output of tungsten boats is significantly impacted by the choice of rivet quality, size, and type.

3. Chemical of Tungsten Boat For Vacuum Industry(max. wt%):

| Al | Fe | Ca | Mg | Mo | Ni | Si | C | N | O | W |

| 0.002 | 0.005 | 0.003 | 0.002 | 0.01 | 0.003 | 0.003 | 0.005 | 0.003 | 0.005 | 99.95 |

![]()

![]()

![]()

![]()

riveted W boat sintered W boat fold W boat riveted Mo boat