-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

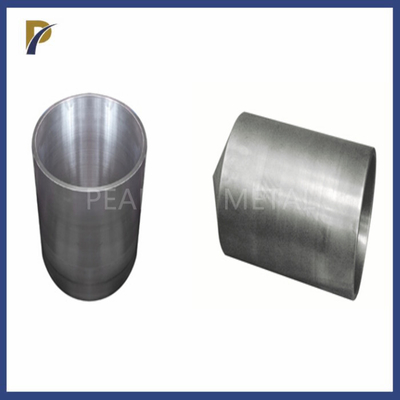

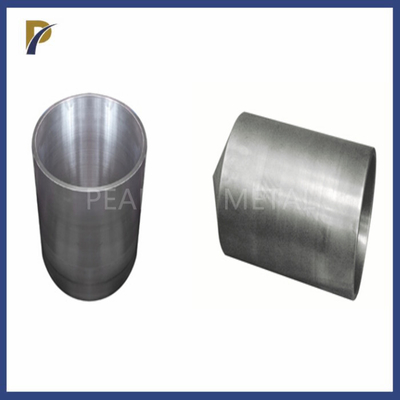

99.95% Pure Wolfram Tungsten Crucible For Single Crystal Growth Furnace Sintered Tungsten Crucibles High Purity Tungsten

| Name | Tungsten Crucible For Single Crystal Growth Furnace | Material | Pure Tungsten |

|---|---|---|---|

| Density | 17.8 G/cm3~18.3 G/cm3 | Purity | 99.95% |

| Diameter | 30~500mm | Thickness | 2~30mm |

| Height | <1000mm | Roughness | <1.6 |

| Highlight | Pure Tungsten Crucible,99.95% Tungsten Crucible,wolfram tungsten crucible |

||

Tungsten Crucible For Single Crystal Growth Furnace

1. Tungsten Crucible For Single Crystal Growth Furnace Description:

Pure tungsten is used to make tungsten crucibles, which have the same properties as pure tungsten. It is a crucial component of the thermal field for sapphire crystal development, the smelting of rare earths, the continuous melting of quartz, and the high temperature heat treatment furnace. Under 2600°C, it can be employed in vacuum or inert gas.

We can offer crucibles with ordinary density (about 18.3 g/cm3) and high density (about 18.5 g/cm3) according on the needs of the customer. The interior surface is flawless and unblemished, so even at high temperatures, the contents inside the container won't be harmed. The crucible's deformation resistance has been greatly increased after special processing.

2. Size of Tungsten Crucible For Single Crystal Growth Furnace:

| Purity | Diameter(mm) | Wall thickness (mm) | Height(mm) |

| W≥99.95% | 30-50 | 2-10 | ≤1000 |

| 50-100 | 3-15 | ||

| 100-150 | 3-15 | ||

| 150-200 | 5-20 | ||

| 200-300 | 8-20 | ||

| 300-400 | 8-30 | ||

| 400-450 | 8-30 | ||

| 450-500 | 8-30 |

![]()

![]()

3. Manufacturing process and equipment of Tungsten Crucible For Single Crystal Growth Furnace:

| Item | Process | Equipment | Quality Check point |

| 1 | Tungsten powder | 1 Purity of tungsten powder | |

| 2 | Sieving | High frequency vibrating screen | 2 Fsss,HB |

| 3 | Mixed powder | V shape mixer | 3 Green strength |

| 4 | Isostatic pressing | Isostatic pressing machine | 1 Measurement of rough-processed billet |

| 5 | Rough billet lathing | CNC vertical turning machine | 2 Surface quality of rough-processed billet |

| 6 | IF sintering | IF induction sintering furnace | 1 Outside measurements of finished product |

| 7 | Competitive products lathing | High-accuracy vertical turning machine | 2 Surface quality and roughness of finished product,density |

| 8 | Package | 3 Show certificate of quality |

4. Production Process of Tungsten Crucible For Single Crystal Growth Furnace:

One of the most important preparation methods for industrial production of tungsten crucibles today is the sintering method. The sintered tungsten crucible is first assembled into the mold according to the size required by the product, and then the tungsten powder raw materials that meet the national standard are loaded into the mold and sealed. The next step is to put it into an isostatic press with a pressure of 180-250MPa to start the pressing operation, and then put the green compact into a high-temperature induction sintering furnace with a heating rate of 80-150℃/h for sintering, and the high temperature holding time Best for 4-8 hours. Finally, it is processed according to the product requirements. After processing, the quality inspection of the appearance, size, density, etc. of the finished product is carried out.

The raw material used in the sintered tungsten crucible is tungsten powder. After forming by firing, the tungsten crucible is obtained by lathe processing. The biggest advantage of the sintered tungsten process is that it can produce large-sized tungsten crucibles. Sintered tungsten crucibles are preferred by many producers because they have a longer service life, a more consistent quality, and greater diameters as compared to stamped tungsten crucibles. The preparation technology of large-size sintered crucibles in my country has reached the international advanced level, and the quality and production capacity of this type of tungsten crucibles are also at a high level.

Please click below button for learn more our products.

![]()