-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

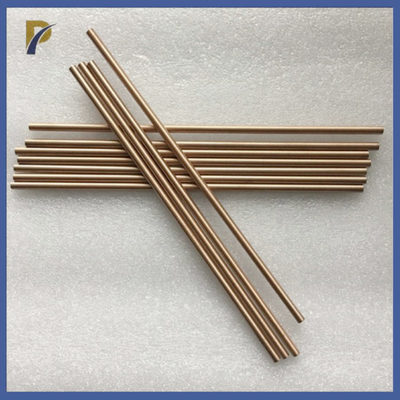

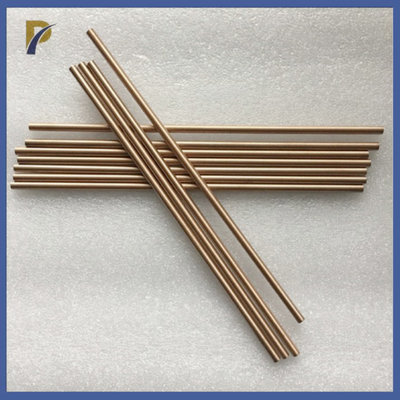

Polished W80Cu20 Tungsten Copper Alloy Rod Density 15.5g/Cm3 Copper Tungsten Electrode Copper Tungsten Bar

| Name | Density 15.5g/Cm3 W80Cu20 Tungsten Copper Alloy Rod | Material | Tungsten Copper Alloy |

|---|---|---|---|

| Grade | W80Cu20 | Shape | Rod/bar |

| Density | 15.5g/cm3 | Surface | Polished |

| Diameter | 5~50mm | Function | Copper Alloy For Electrical And Thermal Conductivity |

| Highlight | 15.5g/Cm3 Tungsten Copper Alloy,W80Cu20 Tungsten Copper Alloy Rod,Polished Tungsten Copper Rod |

||

Density 15.5g/Cm3 W80Cu20 Tungsten Copper Alloy Rod

1. Description Of Density 15.5g/cm3 W80Cu20 Tungsten Copper Alloy Rod:

W80 tungsten-copper alloy rod is a rod composed of 80% tungsten and 20% copper, of which 20±2% copper and 0.5% impurity tungsten. Due to the high content of tungsten in W80 tungsten copper alloy, the characteristics of high hardness and high melting point of tungsten itself are also reflected in it. Its density can reach 15.5g/cm3, and its hardness is not lower than HB220. However, due to the decrease of copper content, the electrical conductivity and thermal conductivity have also changed. The electrical conductivity is about 34IACS%, the thermal conductivity is 190-210 (wm/k), the thermal expansion coefficient is 8.0-8.5 (10-6K), and the bending strength can reach 980, the softening temperature is not lower than 900 ℃.

2. Technical Features Of Density 15.5g/cm3 W80Cu20 Tungsten Copper Alloy Rod:

Our company can currently produce rods with a diameter of 5-50 mm and a maximum length of 300 mm. Tungsten copper alloy rods can be processed into electric spark discharge electrodes and tungsten copper spot welding electrodes. The standard tolerance for the diameter of tungsten copper rods below 16 mm is: (0,+0.02) mm. The diameter tolerance above 18 mm is (-0.5, +0.5) mm. The small tungsten copper rod is bright gray and white, and the thick rod is copper yellow. This is caused by different processing methods and does not affect the use.

Tungsten copper technical indicators:

| Grade |

Content (%wt.) |

Density(g/cm3) ≥ |

Hardness(HRB) ≥ |

Conductivity(%IACS) ≥ |

Class | RWMA |

| W50 | W50,remain Cu | 11.85 | 65 | 55 | ||

| W55 | W55,remain Cu | 12.30 | 70 | 50 | 10 | 10.74450 |

| W70 | W70,remain Cu | 13.85 | 85 | 45 | ||

| W75 | W75,remain Cu | 14.50 | 90 | 40 | 11 | 11.74400 |

| W80 | W80,remain Cu | 15.5 | 98 | 34 | 12 | 12.74350 |

| W85 | W85,remain Cu | 15.90 | 240HB | 30 | ||

| W90 | W90,remain Cu | 16.75 | 260HB | 27 |

![]()

![]()

3. Application Of Density 15.5g/cm3 W80Cu20 Tungsten Copper Alloy Rod:

1). Cutting

Tungsten-copper alloys may be flawed due to impact or excessive processing load when making sharp corners and thin walls. Tungsten-copper-silver-tungsten alloy products when drilling through holes.

Please pay attention to feed the load force when the hole is about to pass to avoid processing defects.

Tungsten copper alloy is non-magnetic, please confirm that the product is firmly fixed before operation.

2). EDM, wire cutting

The discharge and wire cutting speed of tungsten copper silver tungsten products are relatively slow, which is a normal phenomenon.

Please click below button for learn more our products.

![]()