-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

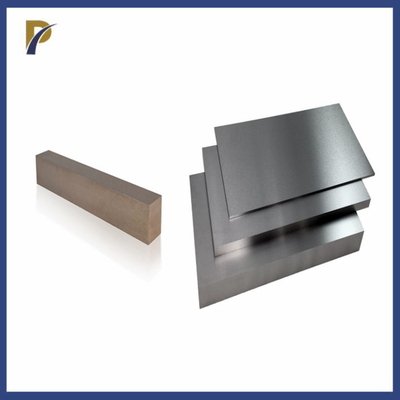

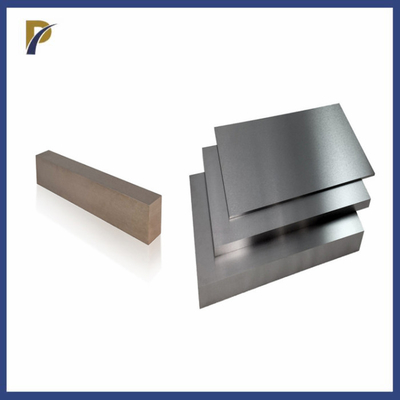

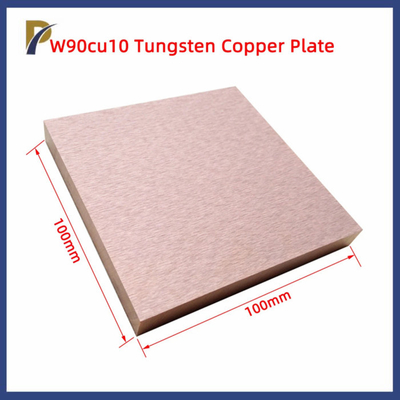

80W20Cu Tungsten Copper Alloy Plate 2mm 3mm 5mm 10mm For EDM Electrode

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

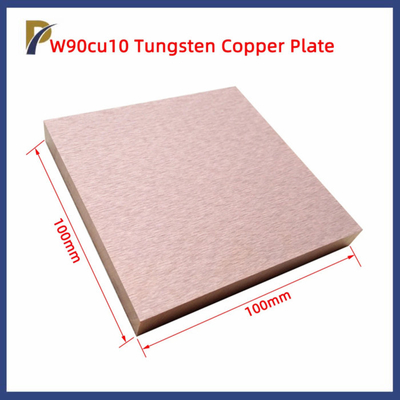

x| Name | 80W20Cu Tungsten Copper Alloy Plate Thickness 2mm,3mm,5mm,10mm For EDM Electrode | Material | Tungsten Copper Alloy |

|---|---|---|---|

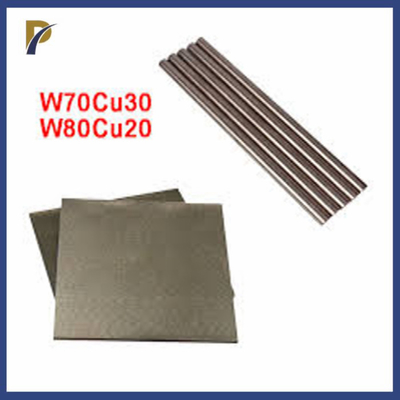

| Grade | 75WCu,80WCu,90WCu,70WCu,85WCu | Surface | Bright |

| Thickness | 2~50mm | Width | <200mm |

| Length | <500mm | Craft | Infiltration |

| Highlight | 2mm Tungsten Copper Alloy Plate,EDM Electrode Tungsten Copper Alloy Plate,Tungsten Copper Alloy Plate 10mm |

||

80W20Cu Tungsten Copper Alloy Plate Thickness 2mm,3mm,5mm,10mm For EDM Electrode

1. Introduction of Tungsen Copper Alloy Plate:

Tungsten-copper alloy plate combines the advantages of metal tungsten and copper, among which tungsten has a high melting point (tungsten melting point is 3410°C, copper melting point is 1080°C) and high density (tungsten density is 19.25g/cm, copper density is 8.92/cm3) Copper has excellent electrical and thermal conductivity, tungsten-copper alloy (the general composition range is WCu7~WCu50) has uniform microstructure, Military high-temperature resistant materials are frequently utilized because of their high temperature resistance, strength, arc ablation resistance, and density, as well as their moderate electrical and thermal conductivity. Electrical alloys are frequently utilized as parts and components in the aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment, and other industries. They are also used for high-voltage switches, electrical processing electrodes, and microelectronic materials.

![]()

![]()

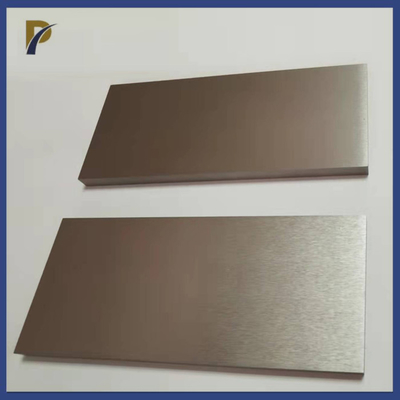

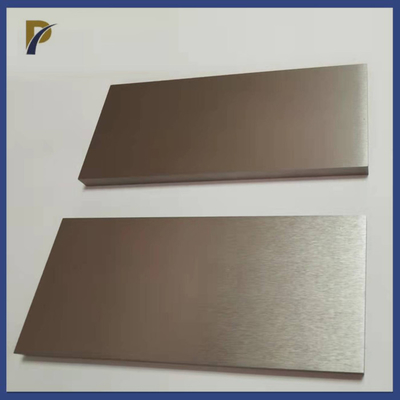

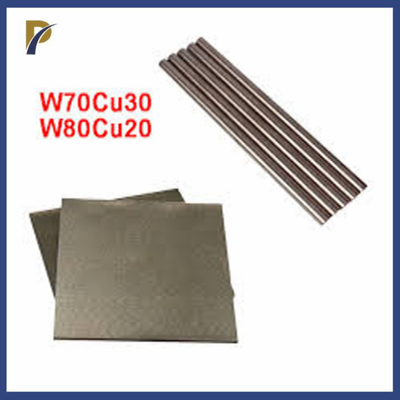

2. Grade and Performance of Tungsten Copper Alloy Plate:

Tungsten-copper alloy plates are mainly composed of tungsten and copper, and the properties of different grades are also different. The following table introduces the different properties of different grades in detail.

|

Name

|

Grade

|

Cu

content

|

Impurities

|

W

content

|

Density

|

Resistance

|

Conductance

|

Hardness HB

|

Bending strength

|

|

Copper Tungsten50

|

CuW50

|

50±2

|

0.5

|

Remain

|

11.85

|

3.2

|

54

|

1128

|

|

|

Copper Tungsten55

|

CuW55

|

45±2

|

0.5

|

Remain

|

12.30

|

3.5

|

49

|

1226

|

|

|

Copper Tungsten60

|

CuW60

|

40±2

|

0.5

|

Remain

|

12.75

|

3.7

|

47

|

1373

|

|

|

Copper Tungsten65

|

CuW65

|

35±2

|

0.5

|

Remain

|

13.30

|

3.9

|

44

|

1520

|

|

|

Copper Tungsten70

|

CuW70

|

30±2

|

0.5

|

Remain

|

13.80

|

4.1

|

42

|

1716

|

790

|

|

Copper Tungsten75

|

CuW75

|

25±2

|

0.5

|

Remain

|

14.50

|

4.5

|

38

|

1912

|

885

|

|

Copper Tungsten80

|

CuW80

|

20±2

|

0.5

|

Remain

|

15.15

|

5.0

|

34

|

2158

|

980

|

|

Copper Tungsten85

|

CuW85

|

15±2

|

0.5

|

Remain

|

15.90

|

5.7

|

30

|

2354

|

1080

|

|

Copper Tungsten90

|

CuW90

|

10±2

|

0.5

|

Remain

|

16.75

|

6.5

|

27

|

2550

|

1160

|

- Mature pressing-sintering-infiltration process control, no holes inside the product

- High conductivity and EDM speed

- Good flexibility, simplicity in shaping

3.Applictaion of Tungsten Copper Alloy Plate:

1). Electrode material: It is used in flat sheet electrode discharge machining and high hardness materials. Products that have undergone electroprocessing have a high-quality, high-precision, low-loss, and cost-effective surface finish.

2). Contact materials: arc contacts and vacuum contacts of high and medium voltage switches or circuit breakers, circuit board welding and electrical contact points.

3). Welding materials: submerged arc welding machine, gas shielded welding machine welding nozzle, wireless resistance factory (production of carbon film resistance, metal coating resistance) resistance butt welding material (copper tungsten alloy welding disc).

4). Steel wire wrapped into a variety of shapes is used as a guide material for materials protection.

4. Production craft of Tungsten Copper Alloy Plate:

Tungsten copper plate mainly adopts powder mixing-pressing-sintering-infiltration process route. The tungsten-copper mixed powder is sintered in liquid phase at 1300-1500° after compression molding. The uniformity of the material prepared by this method is not good, there are many closed spaces, and the density is usually lower than 98%. It can improve the sintering activity, thereby increasing the density of tungsten-copper and molybdenum-copper alloys. However, the activation and sintering of nickel will significantly reduce the electrical and thermal conductivity of the material, and the introduction of impurities by mechanical alloying will also reduce the conductivity of the material; the preparation of powder by oxide co-reduction method is cumbersome, the production efficiency is low, and it is difficult to mass produce.

![]()

![]()

Please click below button for learn more our products.

![]()