-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

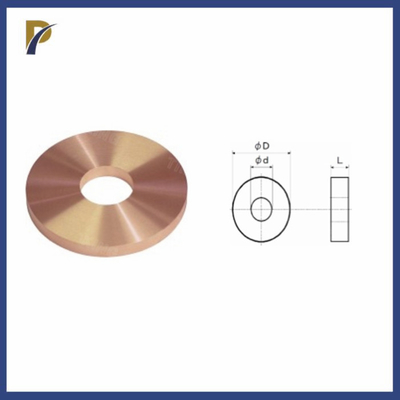

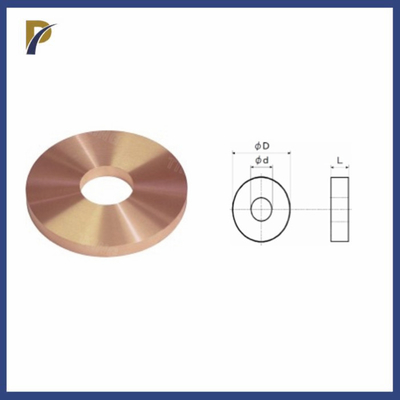

Bright Inlaid Tungsten Copper Alloy Electrode Composite 75 WCu

| Name | Tungsten Copper Inlaid Electrode Copper Tungsten Alloy Electrode Copper Tungsten Composite Electrode | Material | Tungsten Copper Alloy |

|---|---|---|---|

| Grade | 75WCu,80WCu,90WCu,70WCu,Copper Inlaid Tungsten | Color | Metallic Color |

| Size | As Per Customer's Drawing | Surface | Bright |

| Export Port | Any Port In China | ||

| Highlight | Tungsten Copper Alloy Electrode Composite,75 WCu Tungsten Copper Alloy Composite,Bright Inlaid Tungsten Copper Alloy Composite |

||

Tungsten Copper Inlaid Electrode Copper Tungsten Alloy Electrode Copper Tungsten Composite Electrode

1. Information Of Tungsten Copper electrode:

Tungsten copper electrode is a composite material composed of tungsten and copper. Tungsten copper alloy electrode combines the good properties of tungsten and copper, high temperature resistance, arc ablation resistance, high strength, high specific gravity, good electrical and thermal conductivity, and easy processing , and its functions such as sweating, and tungsten high hardness, high melting point, anti-adhesion characteristics, often used to make a certain wear resistance, high and low temperature resistance welding, butt welding electrodes.

![]()

![]()

2. Classification Of Tungsten Copper electrode:

Tungsten Copper Composite Electrode:

The tungsten-copper composite electrode eliminates the problems of pores and cracks in the welding composite used in the past. An electrode made of tungsten, copper, and iron is called a tungsten-copper-iron composite electrode. It has high bonding strength and good electrical conductivity. It combines the advantages of tungsten and copper. It has high temperature resistance, arc ablation resistance, high hardness, high melting point, high strength, High specific gravity, high electrical conductivity, high thermal conductivity, easy cutting, anti-adhesion, and has the characteristics of sweating and cooling.

Tungsten copper inlaid electrode:

The performance of tungsten copper inlaid electrode is guaranteed by the combination of heat treatment and cold processing. It can obtain the best mechanical properties and physical properties. It has the advantages of good uprightness, no bending of thin slices, and high finish when used as an electric spark electrode. It is used in high Precision and mirror surface mold discharge machining, or as large molds and fixtures for projection welding machines, molds for stainless steel and heat-resistant steel, or inlay electrodes. In addition, tungsten copper can be used as general-purpose resistance welding electrodes, mainly as electrodes for spot welding or seam welding of low-carbon steel and coated steel plates, and can also be used as electrode holders, shafts and gasket materials for welding low-carbon steel.

3. Performance comparison Of Tungsten Copper electrode:

| Grade | Density | Hardness | Resistance | Conductivity | Flexural strength |

| g/cm3≥ | HB Kgf/mm2≥ | µΩ.cm≤ | %≥ | Mpa≥ | |

| W50/Cu50 | 11.85 | 115 | 3.2 | 54 | -- |

| W55/Cu45 | 12.30 | 125 | 3.5 | 49 | -- |

| W60/Cu40 | 12.75 | 140 | 3.7 | 47 | -- |

| W65/Cu35 | 13.30 | 155 | 3.9 | 44 | -- |

| W70/Cu30 | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 16.75 | 260 | 6.5 | 27 | 1160 |

4. Process Craft Of Tungsten Copper electrode:

The production process of tungsten-copper electrodes generally adopts powder metallurgy process, mixing tungsten and copper powder evenly, and then sintering them into green bodies through high-temperature sintering process, and finally machining or cutting them into required specifications. The production process of tungsten copper electrodes strictly controls temperature and time to ensure its uniform structure, precise size and stable performance.

Please click below button for learn more our products.

![]()