-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

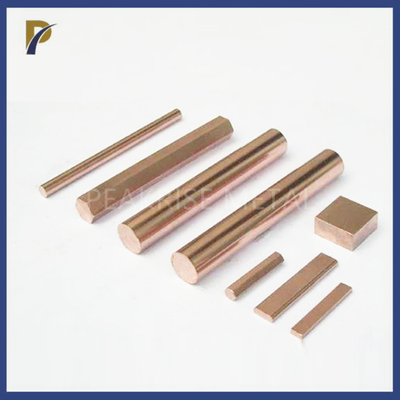

WCu25 WCu30 Diameter 5 - 50mm Tungsten Copper Alloy Bar For Electronic Packaging Aerospace

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | WCu25 WCu30 Diameter 5~50mm Tungsten Copper Alloy Bar For Electronic Packaging | Material | Tungsten Copper Alloy |

|---|---|---|---|

| Grade | 75WCu,80WCu,90WCu,70WCu,W60Cu40,W50Cu50 | Diameter | 2~100mm |

| Length | 50~500mm | Surface | Bright |

| Density | 14.5~18.8g/cm3 | Thermal Conductivity | 200-220W/(m·K) |

| Highlight | 50mm Tungsten Copper Alloy Bar,WCu25 Tungsten Copper Alloy Bar,Aerospace Copper Tungsten Bar |

||

WCu25 WCu30 Diameter 5~50mm Tungsten Copper Alloy Bar For Electronic Packaging

1. Information Of WCu25 WCu30 alloy bar:

WCu25 and WCu30 are common tungsten-copper alloy rod materials, which are mainly composed of tungsten and copper, with high density and good thermal conductivity.

2. Size Of WCu25 WCu30 alloy bar:

WCu25 and WCu30 generally have different diameter and length dimensions.

WCu25: diameter 2-100mm, length 50-500mm;

WCu30: diameter 5-100mm, length 50-500mm.

Different sizes of materials can be selected according to specific application needs.

![]()

![]()

3.Technical Parameters Of WCu25 WCu30 alloy bar:

| WCu25 | WCu30 | ||

| Density | 14.5-15.0g/cm³ | 16.8-17.2g/cm³ | High density means that the material is heavier, but it also means that it has higher quality and better strength |

| Thermal conductivity | 180-190W/(m·K) | 200-220W/(m·K) | High thermal conductivity means that the material has good thermal conductivity and can quickly transfer heat to other parts of the material, thereby improving the heat dissipation effect of the material |

| Thermal expansion coefficient | 6.5-8.5×10^-6/K | 6.5-8.5×10^-6/K | A low coefficient of thermal expansion means that the material deforms less when the temperature changes, giving it better stability and durability. |

| Hensile strength | 790-890MPa | 930-1030MPa | High tensile strength means that the material has good tensile properties and can withstand certain tensile forces and tensile deformations. |

| Hardness | HB180-240 | HB210-280 | High hardness means that the material has good wear resistance and corrosion resistance, and can maintain a long service life in harsh environments. |

The main performance advantages of WCu25 and WCu30 include high thermal conductivity, high strength, good wear resistance and high temperature stability. These properties make WCu25 and WCu30 widely used in thermal management, electronic packaging, aerospace, automatic machinery and other fields. In addition, WCu25 and WCu30 also have good corrosion resistance and can work in some acid and alkali environments.

4. Application Of WCu25 WCu30 alloy bar:

The application fields of WCu25 and WCu30 are very wide. They can be used to manufacture components such as heat conduction plates, package bases and high-voltage contactors of electronic devices to improve the heat dissipation performance and mechanical strength of the devices; they can also be used to manufacture electrodes, brushes and other components to improve their wear resistance and life ; In addition, they can also be used to manufacture high-temperature parts, aero-engine blades and other parts in high-temperature environments to improve their high-temperature stability.

Please click below button for learn more our products.

![]()