-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

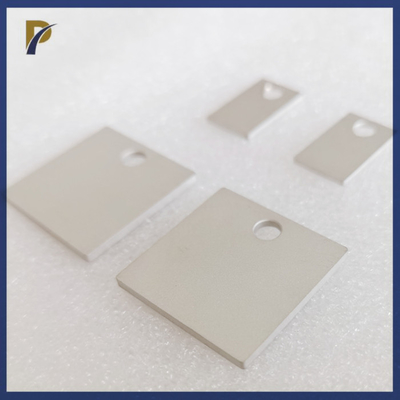

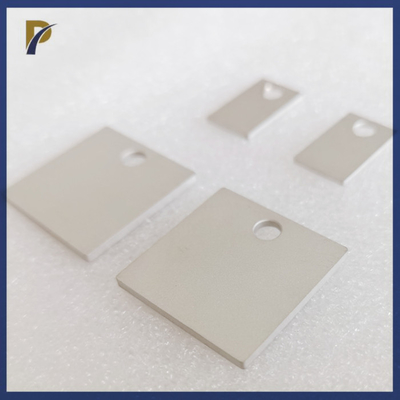

Tungsten Copper Alloy Electronic Packaging Sheet High Density 11.9 - 17.3g/Cm3

| Density | 11.9-17.3g/cm3 | Resistivity | ≤3.2~6.5μΩ·m |

|---|---|---|---|

| Grade | WCu10 WCu20 WCu25 WCu30 WCu35 WCu40 WCu50 Etc. | Impact Strength | ≥30J |

| Name | Tungsten Copper Alloy | Electrical Conductivity | ≥54~≥27%IACS |

| Hardness | ≥260~≥115HB | Thermal Conductivity | 80-300W/mK |

| Highlight | Tungsten Copper Alloy Electronic Packaging Sheet,Powder Metallurgy Tungsten Copper Alloy,Electronic Packaging Alloy Copper Tungsten Sheet |

||

Product Description:

Tungsten copper alloy electronic packaging sheet is a material used in electronic packaging and thermal management. It is usually composed of two metals, tungsten and copper, and is made by powder metallurgy or other processing methods.

Tungsten copper alloy is characterized by good thermal conductivity and high thermal expansion coefficient. Tungsten has a very high melting point and excellent thermal conductivity, while copper has high conductivity and low resistivity. Therefore, tungsten copper alloy can provide good thermal conductivity while maintaining low electrical resistance and electrical conductivity.

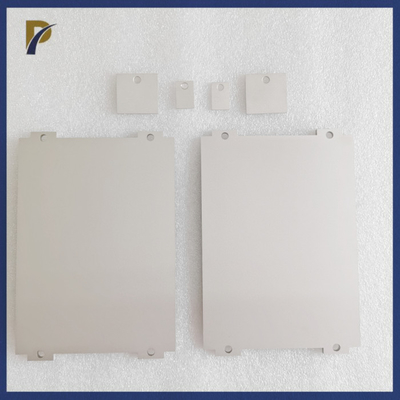

In electronic packaging, tungsten-copper alloy electronic packaging sheets are usually used to manufacture substrates, heat sinks, packaging bases and other components of high-power electronic devices. Its excellent thermal conductivity can help effectively conduct and disperse the generated heat, thereby improving the working efficiency and reliability of electronic devices.

![]()

Features:

- Product Name: Tungsten Copper Alloy Electronic Packaging Sheet

- Surface: Metal color or nickel/silver plating

- Grade: WCu10, WCu20, WCu25, WCu30, WCu35, WCu40, WCu50, etc.

- Resistivity: ≤3.2~6.5μΩ·m

- Density: 11.9-17.3g/cm3

- Bending Strength: ≥1000MPa

- Keywords: WCu20 alloy rod, copper tungsten Electronic package, tungsten copper heat sink

Applications:

In electronic packaging, tungsten-copper alloy electronic packaging sheets are usually used to manufacture substrates, heat sinks, packaging bases and other components of high-power electronic devices. Its excellent thermal conductivity can help effectively conduct and disperse the generated heat, thereby improving the working efficiency and reliability of electronic devices.

In addition, tungsten copper alloy can also be adjusted according to specific application requirements. By adjusting the ratio of tungsten and copper, the thermal expansion coefficient of the alloy can be controlled to better match other materials and reduce thermal stress and thermal cracks.

In summary, tungsten-copper alloy electronic packaging sheet is a material widely used in high-power electronic devices, which has good thermal conductivity and adjustable thermal expansion coefficient, which helps to improve the performance and reliability of electronic devices.

Technical Parameters:

| Name | Tungsten Copper Alloy Electronic Packaging Sheet |

|---|---|

| Surface | Polished |

| Flexural Strength | ≥1160~≥790MPa |

| Tensile Strength | ≥1000MPa |

| Thermal Conductivity | 80-300W/mK |

| Coefficient of Thermal Expansion | 6.3-9.7×10-6/K |

| Young's Modulus | 155-170GPa |

| Bending Strength | ≥1000MPa |

| Density | 11.9-17.3g/cm3 |

| Impact Strength | ≥30J |

| Focus Keywords | Cu10W90 tungsten copper metal alloy electrode, copper tungsten Electronic package, WCu20 alloy rod bar |

Support and Services:

Tungsten Copper Alloy offers technical support and services to ensure product quality, safety, and longevity. Our team of experienced engineers is available to answer questions and provide guidance on product selection, installation, maintenance, and repairs. We provide in-depth technical assistance, including troubleshooting and product testing. Our team can also provide custom design and fabrication services to meet specific application needs. We strive to provide the highest level of customer service and satisfaction.

Packing and Shipping:

Tungsten Copper Alloy products are usually packaged and shipped in boxes, barrels, bags or other appropriate containers. Delivery times vary depending on the specific product and the customer's specific requirements. In general, the packaging and shipping process includes:

1. Inspection of the product to ensure quality and conformity to specifications

2. Wrapping and packaging of the product to protect it during shipment

3. Labeling of the packaging with shipping information

4. Shipment of the product to the customer's location via ground, air, or sea freight

FAQ:

- Q: What is Tungsten Copper Alloy?

- A: Tungsten Copper Alloy is an alloy composed of tungsten and copper, produced by powder metallurgy, melting and sintering, and other forming processes.

- Q: What is the brand name of Tungsten Copper Alloy?

- A: The brand name of Tungsten Copper Alloy is PRM.

- Q: What are the model numbers of Tungsten Copper Alloy?

- A: The model numbers of Tungsten Copper Alloy are WCu10,WCu20,WCu30,WCu25,WCu40 WCu50.

- Q: Where is Tungsten Copper Alloy from?

- A: Tungsten Copper Alloy is from China.

- Q: What are the properties of Tungsten Copper Alloy?

- A: The properties of Tungsten Copper Alloy include good electrical and thermal conductivity, high strength, high fatigue strength, high thermal stability and low thermal expansion coefficient.

-

Please click below button for learn more our products.