-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

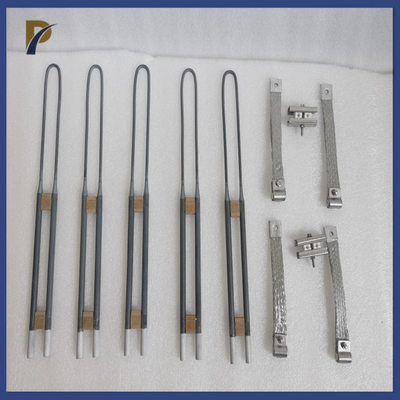

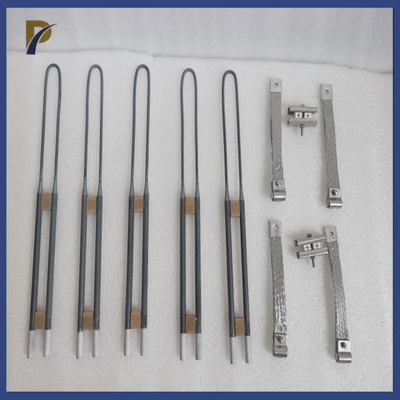

High Temperature Molybdenum Silicide Heating Elements 6 / 12 X 200 X 180 X 40mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Molybdenum Silicide Heating Elements | Size | Φ6/12*200*180*40mm |

|---|---|---|---|

| Density | 5.6~5.8g/cm3 | Bending Strength | 20MPa(20℃) |

| Use Temperature | 1600~1800℃ | Vicker Hardness | 570kg/mm2 |

| Thermal Elongation | 4% | ||

| Highlight | Molybdenum Silicide Heating Elements,High Temperature Molybdenum Silicide Rod,MoSi2 Molybdenum Products |

||

Product Description:

High-temperature heating element MoSi2 heating rod is a resistance heating element that works at high temperature, and is often called a high-temperature molybdenum silicon rod. It has many good properties. High-temperature oxidation resistance. In a high-temperature oxidizing atmosphere, a dense quartz glass protective film will be formed on the surface. The protective film can protect the substrate of the heating rod, and this protective film has the function of regeneration and automatic removal of surface adhesion impurities. effect. The resistivity of the MoSi2 heating rod increases rapidly with the increase of temperature, so that the power of the heating rod is higher at low temperature and the furnace temperature rises faster, while the power becomes smaller at high temperature to prevent the material from overheating. In addition, its resistivity does not change with the use of time, that is, it does not age, so old and new components can be mixed. Compared with silicided carbon heating rods, it avoids the problem of aging of heating elements. Molybdenum disilicide heating rod is often used in electric furnaces because of its low energy consumption, fast heating up, easy maintenance and stable product performance.

Common Size:

| Specifications(φd1/d2*L1*L2*D)mm |

| φ6/12*270*220*30 |

| φ4/9*80*130*25 |

| φ6/12*125*120*30 |

| φ6/12*120*180*30 |

| φ6/12*200*180*40 |

| φ6/12*130*180*40 |

| φ5/10*100*160*30 |

| φ6/12*163*150*30 |

| φ6/12*100*170*30 |

| φ6/12*120*170*40 |

| φ6/12*119*105*30 |

| φ9/18*190*300*50 |

A:Center distance

Lu :cold end length

Le:hot end length

d2:hot end diameter

d1:cold end diameter

We also can process as per customer drawing,custom size.

![]()

![]()

![]()

Applications:

Products made from silicon-molybdenum rod heating elements are widely used in metallurgy, steelmaking, glass, ceramics, refractory materials, crystals, electronic components, semiconductor materials research, manufacturing, and other fields. These products are particularly useful for high-performance precision ceramics, high-grade artificial crystals, production of precision structure cermets, glass fiber, optical fiber, and advanced alloy steel.

Rods made of silicon and molybdenum are highly oxidation resistant. A thick quartz SIO2 protective layer develops on the original's surface in a hot environment to stop MOSI2 from oxidizing further. Surface tension causes the SIO2 protective layer, which has a melting point of 1710 degrees, to melt when the element's temperature exceeds 1700 degrees. As a result, the SIO2 loses its protective properties and melts into droplets. The SIO2 protective layer is renewed as long as the component is employed in an oxidizing environment.

Support and Services :

Molybdenum Products offers a range of technical support and services to meet our customers' needs. Our team of experts are available to provide assistance with the selection of the most suitable product for your application.

We also offer a range of after-sales services such as product warranty and replacement options, repair and maintenance services, and technical support. We strive to provide a high quality of service and to ensure that our customers are completely satisfied with their purchase.

Packing and Shipping:

![]()

FAQ:

- Q: What is the brand name of Molybdenum Silicide Heating Elements ?

- A: The brand name of Molybdenum Silicide Heating Elements is PRM.

- Q: Where is Molybdenum Silicide Heating Elements from?

- A: Molybdenum Silicide Heating Elements are from China.

- Q: What types of Molybdenum Silicide Heating Elements does PRM provide?

- A: PRM provides a variety of Molybdenum Silicide Heating Elements .

- Q: What are the advantages of PRM Molybdenum Silicide Heating Elements ?

- A: PRM Molybdenum Silicide Heating Elements has many advantages, such as high melting point, good thermal conductivity, high strength, and wear resistance.