-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

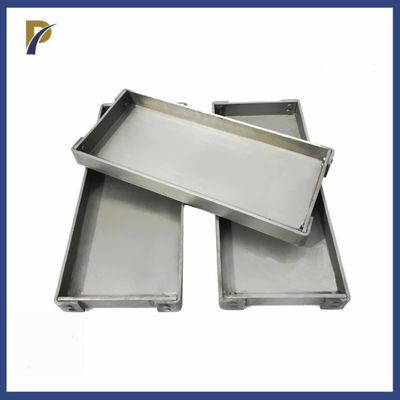

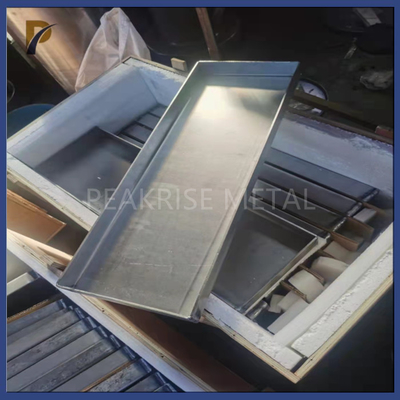

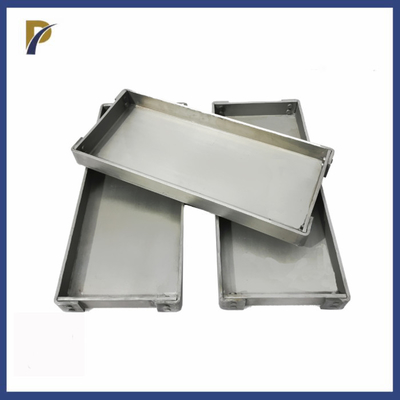

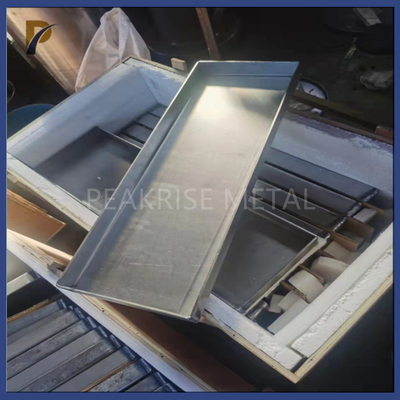

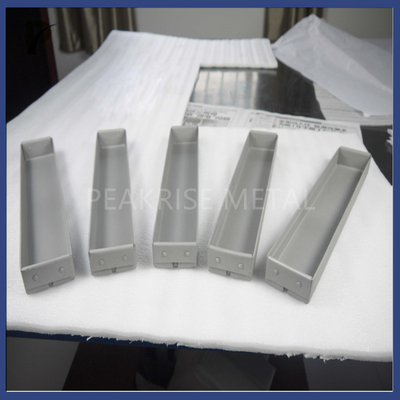

Alkaline Wash Molybdenum Boat For Glass Melting Furnace Excellent Chemical Stability

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Molybdenum Boat For Glass Melting Furnace | Tolerance | +/-0.3mm |

|---|---|---|---|

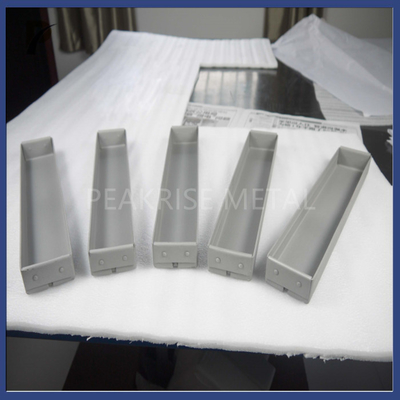

| Processed | Bending, Welding Or Riveting | Shape | Boat |

| Application | Glass Melting Furnace | Surface | Alkaline Wash |

| Thickness | 2~6mm | Size | According To Customer |

| Highlight | Welding Molybdenum Boat,Glass Melting Furnace Molybdenum Boat,Alkaline Wash Molybdenum Trays |

||

Product Description:

Molybdenum boats are used in the glass industry for glass melting furnace applications. They are vessels made of high-purity molybdenum with excellent heat resistance and chemical stability and dimensional stability, able to withstand the high temperature and corrosion of molten glass, and provide stable and reliable vessels. They help ensure uniform heating and quality control of molten glass and are widely used in various links in the glass industry.

| Grade | Main chemical content% | Impurity content(<%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remain | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remain | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remain | — | — | — | 0.4~1.2 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

![]()

![]()

Applications:

Glass Manufacturing: They are widely used in the glass manufacturing process, including the production of flat glass, glass fiber, optical fiber, container glass, etc.

Glass processing: Molybdenum boats carry and transport molten glass during glass processing, such as stretching, forming, molding and other processes.

Advantage:

High temperature resistance: Molybdenum has a very high melting point, about 2623°C (4753°F), which can withstand and carry glass melt in high temperature environment without melting or deforming.

Chemical stability: Molybdenum boats have excellent chemical stability, which can resist the erosion and dissolution of glass and other molten substances, thus prolonging the service life.

Wear resistance: The molybdenum boat can resist the abrasion and wear of molten glass, and has a long service life.

Thermal conductivity: Molybdenum has good thermal conductivity, which can effectively transfer heat to the glass melt, keep the temperature uniform, and help control the quality of the glass.

Dimensional stability: molybdenum boats have a low coefficient of thermal expansion under high temperature conditions and good dimensional stability, which helps to keep the shape and size of the container unchanged.