-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

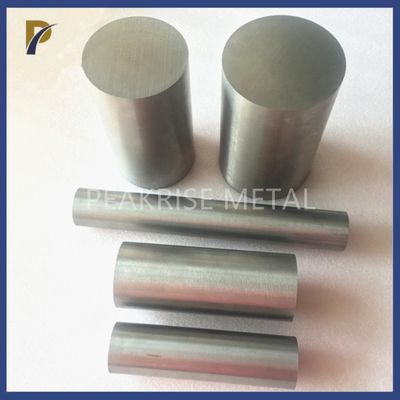

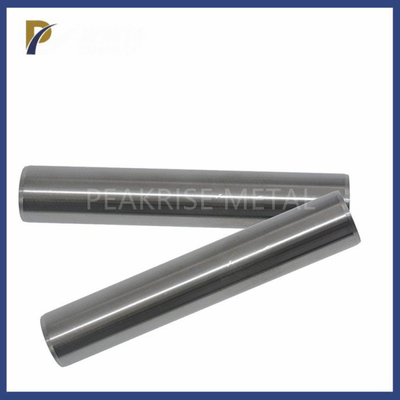

Diameter 20mm TZM Titanium Zirconium Molybdenum Alloy Bar Tzm Alloy Rod Tzm Metal Rod Molybdenum Alloy Rod Dia15mm 20mm

| Name | Titanium Zirconium Molybdenum Alloy Bar Diameter 20mm | Material | Titanium Zirconium Molybdenum Alloy |

|---|---|---|---|

| Grade | TZM | Diameter | 2.0-300mm |

| Length | 10mm-2500mm | Surface | Bright,Black |

| Standard | ASTM B387 | MOQ | 1kg |

| Highlight | TZM Titanium Zirconium Molybdenum Alloy,20mm Titanium Zirconium Molybdenum Alloy,TZM Bar |

||

Titanium Zirconium Molybdenum Alloy Bar Diameter 20mm

1.The Titanium Zirconium Molybdenum Alloy Bar Diameter 20mm is described as follows:

Black surface, alkali washing, automobile polishing, and grinding for bars.

Titanium Zirconium Molybdenum Alloy Bar Requirements: Oxide coating and mild forging hammer marks are permitted on the surface of the forged molybdenum bar. The polished molybdenum bar's surface has a metallic sheen and no discernible oxidation.There should be no delamination, cracks, burrs and other surfaces on both surfaces. Longitudinal cracks and other defects.

2. Tolerances for Diameter and Out-Of-Roundness of Titanium Zirconium Molybdenum Alloy Bar Dia.20mm:

| Diameter inches(mm) | Tolerance in inches (mm) | ||

| Diameter | Out of Roundness | ||

| + | - | ||

| 0.020~1/16 (0.51~1.59) | 0.001(0.02) | 0.001(0.02) | 0.001(0.02) |

| ≥1/16~9/32 (1.59~7.14) | 0.002(0.05) | 0.002(0.05) | 0.004(0.10) |

| ≥9/32~13/32 (7.14~10.32) | 0.010(0.25) | 0.005(0.13) | 0.008(0.20) |

| ≥13/32~5/8 (10.32~15.9) | 0.010(0.25) | 0.005(0.13) | 0.012(0.30) |

| ≥5/8~7/8 (15.9~22.2) | 0.015(0.38) | 0.005(0.13) | 0.015(0.38) |

| ≥7/8~1 (22.2~25.4) | 0.020(0.51) | 0.005(0.13) | 0.015(0.38) |

| ≥1~11/8 (25.4~34.9) | 0.020(0.51) | 0.010(0.25) | 0.018(0.46) |

| ≥11/8~3/2 (34.9~38.1) | 0.020(0.51) | 0.015(0.38) | 0.020(0.51) |

| ≥3/2~13/8 (38.1~41.3) | 0.025(0.64) | 0.015(0.38) | 0.020(0.51) |

| ≥13/8~2 (41.3~50.8) | 0.030(0.76) | 0.020(0.51) | 0.025(0.64) |

| ≥2~5/2 (50.8~63.5) | 0.032(0.81) | 0.032(0.81) | 0.025(0.64) |

| ≥5/2~13/4(63.5~82.6) | 0.032(0.81) | 0.032(0.81) | 0.027(0.69) |

| ≥13/4~7/2 (82.6~88.9) | 0.045(1.14) | 0.045(1.14) | 0.040(1.02) |

3. Mechanical behavior of Titanium Zirconium Molybdenum Alloy Bar Dia.20mm:

| Grade | Condition | Dia. Inches(mm) | Tensile strength min. Mpa | Yield Strength min. Mpa | Elongation % |

| TZM |

SR (Stress relief) |

3/16~7/8 (4.76~22.2) | 790 | 690 | 18 |

| ≥7/8~9/8 (22.2~28.6) | 760 | 655 | 15 | ||

| ≥9/8~15/8 (28.6~47.6) | 690 | 585 | 10 | ||

| ≥15/8~23/8 (47.6~73.0) | 620 | 550 | 10 | ||

| ≥23/8~7/2 (73.0~88.9) | 585 | 515 | 5 |

![]()

![]()

4. Classification of Titanium Zirconium Molybdenum Alloy Bar Dia.20mm:

TZM molybdenum alloy rod can be divided into the following types according to the degree of processing:

Sintered TZM alloy rod: The sintered TZM rod is a rod without subsequent processing, and the surface is gray-black without metallic luster.

Forged TZM alloy rod: After forging, the TZM rod will have a layer of oxide on the surface, and the surface will show a black metal-free color.

Polished TZM alloy rod: The TZM rod can be polished one or more times according to the surface state and quality requirements, and the surface of the polished TZM rod is silver-gray metallic luster.

Polishing TZM alloy rods: Polishing TZM rods refers to polishing the rods to reduce the surface roughness of the alloy rods, thereby obtaining bright and flat TZM rods.

Alkali-washed TZM alloy rods: Alkali-washed TZM rods are obtained through the alkali-washing process. The surface of the alkali-washed TZM rods has a gray metallic luster and is relatively smooth.

Do you want to know more about our products?

![]()