-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

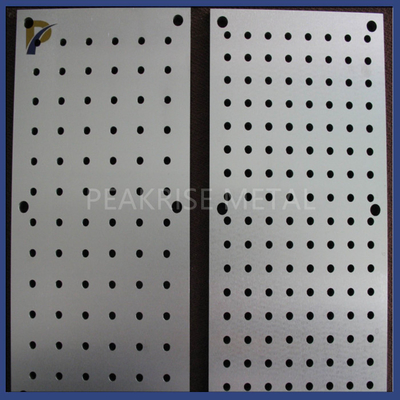

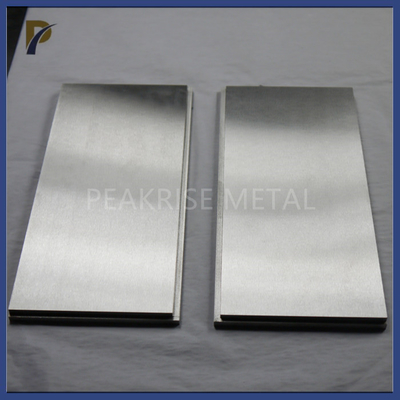

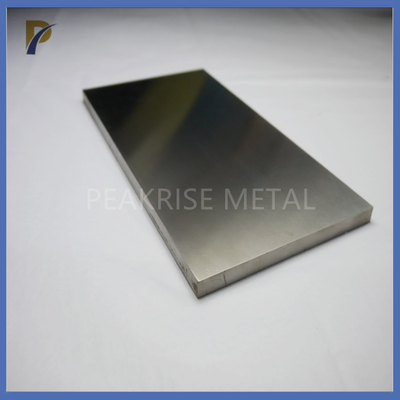

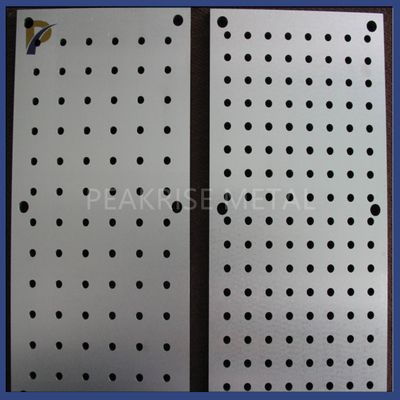

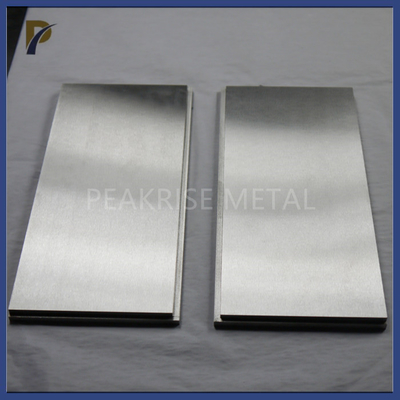

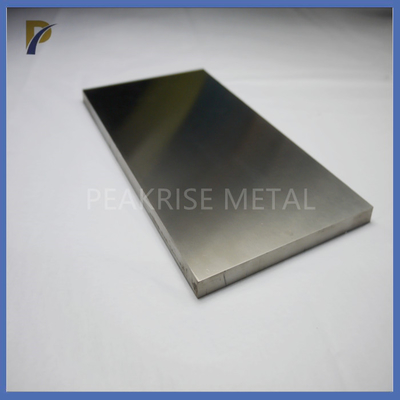

Polished Surface Planar Molybdenum Products Plate Target Moly Plate Molybdenum Sputterin Molybdenum Plateg Targets

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Planar Molybdenum Plate Target | Material | Pure Molybdenum |

|---|---|---|---|

| Purity | 99.95% | Density | 10.2g/cm3 |

| Surface | Polished | Shape | Planar Target |

| Thickness | 3~80mm | Export Port | Any Port In China |

| Highlight | Planar Molybdenum Plate,Molybdenum Target 80mm,Polished Molybdenum Plate Target |

||

Planar Molybdenum Plate Target

1. Description Of Planar Molybdenum Plate Target:

Planar molybdenum targets mainly refer to circular targets and rectangular targets with a certain thickness. The flat target is connected to the sputtering equipment by means of threads, etc., and the film-forming layer is attached to the substrate by sputtering under vacuum conditions, and after that, the film is altered (via etching) in order to suit varied demands.

2. Size Of Planar Molybdenum Plate Target:

Thickness : 3~80mm

Width: 50~350mm

Length: <2500mm

Other size can be processed by customer's request.

Purity: 99.95%

Density: 10.2g/cm3

Use temperature: 1100~1800℃

Standard: ASTM B386

Surface: Polished

Grade: Mo1,TZM,MoLa,361,364

![]()

![]()

3. Production Steps Of Planar Molybdenum Plate Target:

1). Load the raw material into a rubber mold sleeve to prepare a solid powder molybdenum slab;

2). Then use a cold isostatic pressing machine to form, the pressure is 300-400Mpa, and the solid slab is formed after 8 minutes;

3). Put the formed solid slab into the intermediate frequency sintering furnace, pass hydrogen into the furnace, the heating temperature is 2300 ° C, the heating time is 28 hours, and then the water circulation is used to cool down for 10 hours, and then it is cooled to room temperature. body spare;

4). Heat the processed formed slab to 1500°C for 2 hours, take it out and roll it into shape by a hot rolling mill;

50. The processed slab is machined, and the molybdenum plane target is completed.

4. Application Of Planar Molybdenum Plate Target:

Planar Molybdenum plate targets can be used in the medical field for breast examinations, X-ray Planar Molybdenum plate targets to examine breasts, as a non-invasive means of examination, It can more completely and properly depict the overall breast's structural makeup.At present, Planar Molybdenum plate targets has become one of the most effective and reliable methods for diagnosing breast lesions. In foreign countries, this technology has become a standard item of breast examination.

Planar Molybdenum plate target, also known as molybdenum sputtering target, can form thin films on various substrates. This sputtering film can be widely used in electronic components and electronic products, such as TFT-LCD (Thin Film Transitor-Liquid Crystal Displays, Thin film semiconductor tube - liquid crystal display), plasma display screen, inorganic light emitting diode display, field emission display, thin film solar cell, sensor, semiconductor device and field effect transistor gate with tunable work function, etc.

Sputtering targets are used for magnetron sputtering coating, which is a new type of physical vapor deposition (PVD) method.

![]()

![]()

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten and molybdenum non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tungsten alloy, molybdenum alloy and other more than 100 kinds of products.In 2010, with the surge in export sales of products in this industry, we began to focus on foreign trade export business,provide high-quality non-ferrous metal products for the international market.After years of development,at present, it has become a comprehensive non-ferrous metal production enterprise integrating manufacturing and processing, material research and development, product testing, and stock inventory.The development of nearly ten years reminds us that high-quality products and services are always our top priority,at the same time, we continue to expand into new fields and provide high-quality products and services for more domestic and global customers.Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customers.

Peakrise Metal has a variety of production equipment, such as intermediate frequency sintering furnace, vacuum arc melting furnace, plasma electron beam melting furnace, vacuum annealing furnace, various rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, Shears, Stamping Equipment, Cutting Equipment, Grinders, Straightening Machines, CNC, etc.

Please click below button for learn more our products.

![]()