-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Custom Shaped TZM Molybdenum Alloy Process Machined Parts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Process Machined Parts TZM Alloy Custom Shaped Parts TZM Molybdenum Alloy | Material | Titanium Zirconium Molybdenum Alloy |

|---|---|---|---|

| Grade | TZM | Shape | Process Machined Parts |

| Size | As Per Customer's Drawing | Surface | Bright |

| MOQ | 1pc | Export Port | Any Port In China |

| Highlight | TZM Molybdenum Alloy Machined Parts,Custom Shaped TZM Molybdenum Alloy,Bright TZM Alloy Custom Parts |

||

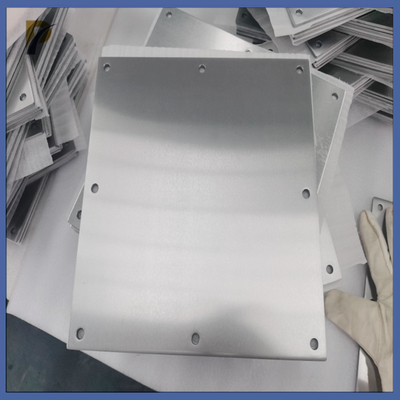

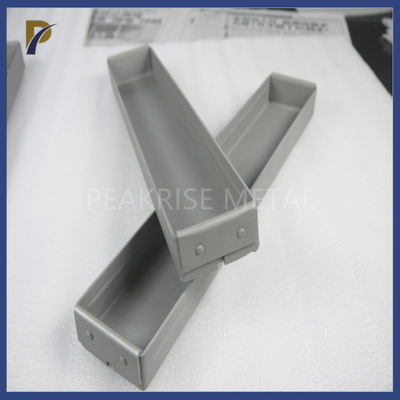

Process Machined Parts TZM Alloy Custom Shaped Parts TZM Molybdenum Alloy

1. Introduction Of TZM Alloy Custom Shaped Parts:

TZM alloy is a high-temperature alloy composed of three elements: tungsten (W), molybdenum (Mo) and titanium (Ti), so it is also called tungsten-molybdenum-titanium alloy. Due to its excellent high temperature performance and mechanical properties, TZM alloy is widely used in aerospace, nuclear energy, shipbuilding, chemical industry, electronics and other fields, among which processed parts and special-shaped parts are important fields of application.

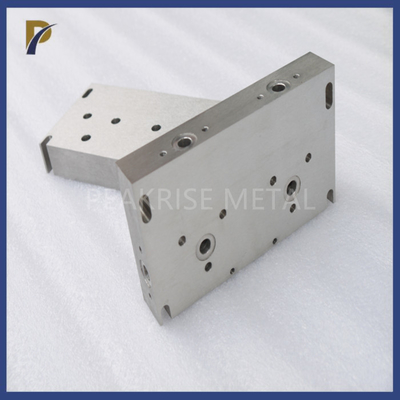

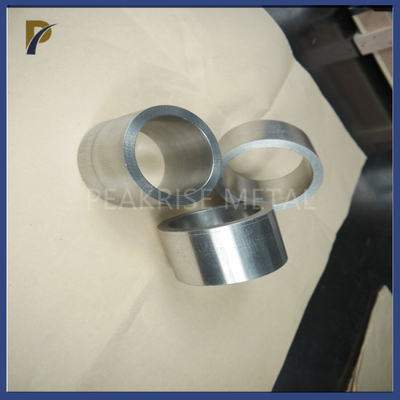

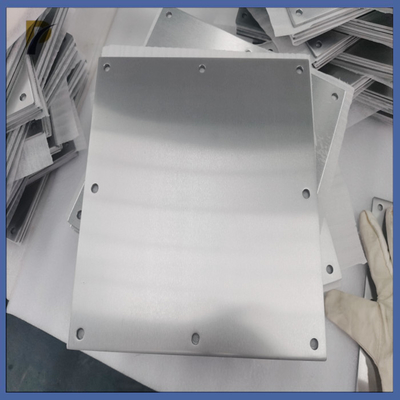

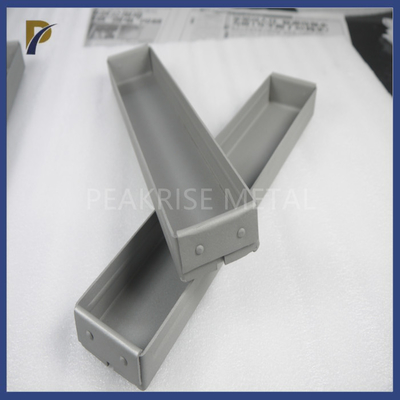

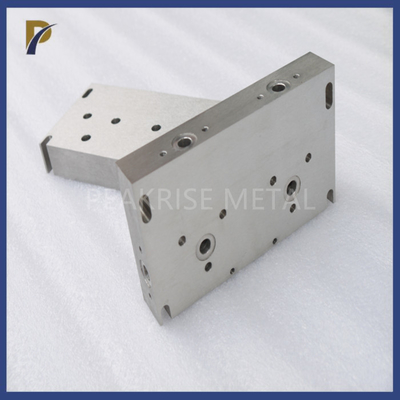

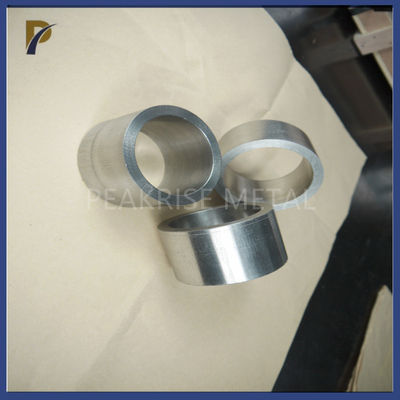

Processed parts refer to mechanical parts made of TZM alloys in various shapes and sizes according to different processing requirements. These processed parts are usually produced according to the design drawings or requirements provided by customers, including various bearings, valves, pump bodies, rotors, shafts, gears, etc., and can also be customized according to customer needs.

2. Size Of TZM Alloy Custom Shaped Parts:

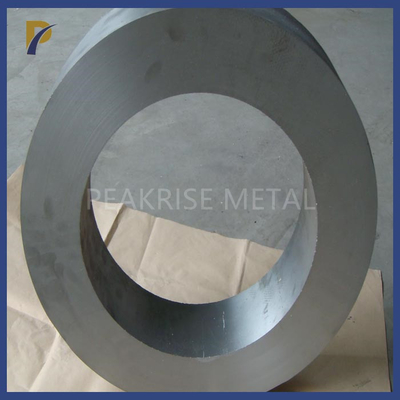

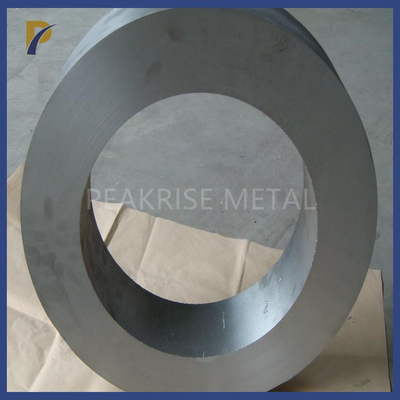

The size of TZM alloy processed parts usually ranges from a few millimeters to hundreds of millimeters, and can be processed according to customer needs. The specific size and shape can be produced according to the drawings or samples provided by customers.

Because TZM alloy has good high-temperature performance and mechanical properties, the processed parts can be used in harsh environments such as high temperature, high pressure and strong corrosion, and have a long service life.

![]()

![]()

![]()

![]()

3. The advantages of TZM alloy processing parts mainly include the following aspects:

Good high-temperature performance: TZM alloy has good high-temperature oxidation resistance, creep resistance and thermal fatigue resistance, and can work stably for a long time in a high-temperature environment.

Excellent mechanical properties: TZM alloy has relatively good mechanical properties such as strength, hardness, toughness and ductility, which can meet the needs of various high-strength and high-wear-resistant mechanical parts.

Good corrosion resistance: TZM alloy has good acid resistance, alkali resistance and corrosion resistance, and can work stably in harsh environments such as strong acid and strong alkali.

Easy to process and weld: TZM alloy has good processability and weldability, and can easily produce various complex shapes of parts.

4. Application Of TZM Alloy Custom Shaped Parts:

TZM is a tungsten alloy with high strength and high temperature stability, and its main components are tungsten, zirconium and molybdenum. Due to its material properties, TZM is often used in the manufacture of high-temperature and high-pressure components for industrial equipment and aerospace.

In industrial manufacturing, TZM alloys are usually used to manufacture high-temperature furnaces, vacuum furnaces, high-temperature gas reactors, high-temperature heating elements, etc. At the same time, TZM alloys are also widely used in the electronics industry, such as X-ray tubes, electron beam processors, vacuum electronic devices, cathodes, etc. In the field of aerospace, TZM alloys can be used to manufacture components such as turbine blades, combustion chambers, and aeroengine propellers in jet engines.

In addition, TZM alloy can also be used to manufacture some special processed parts and special-shaped parts. For example, TZM alloy can be made into TZM alloy bolts, TZM alloy nuts, TZM alloy screws, TZM alloy studs and other fasteners, which are often used in high temperature and high pressure environments. In addition, TZM alloy can also be made into various special-shaped parts, such as TZM alloy tube, TZM alloy rod, TZM alloy plate, TZM alloy foil, etc. These special-shaped parts can be used to manufacture high-temperature containers, reactors, heat insulation layers, etc.

![]()

![]()

Do you want to know more about our products?

![]()