-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

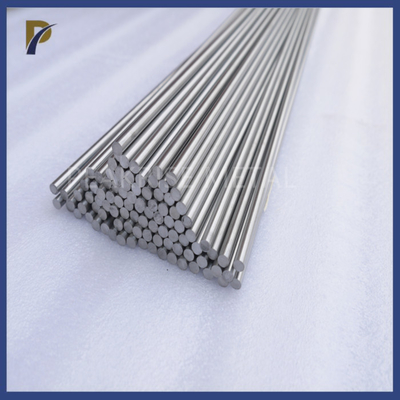

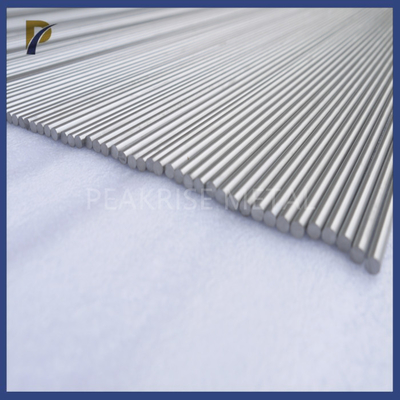

Diameter 15mm TZM Alloy Rod For High Temperature Furnace Heating Device

| Name | TZM Alloy Rod High Temperature Furnace Heating Device | Material | Titanium Zirconium Molybdenum Alloy |

|---|---|---|---|

| Mo Purity | 90% | Diameter | 2~100mm |

| Length | ≤2000 Mm | Surface | Polished |

| Density | 10.2g/cm3 | Melting Point | 2617℃ |

| Highlight | 15mm TZM Molybdenum Alloy,High Temperature Resistant TZM Molybdenum Alloy,Furnace Heating Device TZM Molybdenum Alloy |

||

TZM Alloy Rod High Temperature Furnace Heating Device

1. Introduction Of TZM Alloy:

TZM alloy has the characteristics of high melting point, high strength, high elastic modulus, small linear expansion coefficient, low vapor pressure, good electrical and thermal conductivity, strong corrosion resistance and good high-temperature mechanical properties, so it can be widely used in many fields.

TZM alloy rods usually have a diameter of 2mm-100mm and a length of 1000mm-2000mm. Alloy rods of other specifications can also be customized according to different uses and requirements.

2.Mechanical Properties Of TZM Alloy Rod:

|

Elongation

/%

|

Elastic Modulus

/GPa

|

Yield Strength

/MPa

|

Tensile Strength

/MPa

|

Fracture Toughness

/(MP·m1/2)

|

|

<20

|

320

|

≥780 MPa

|

685

|

5.8~29.6

|

![]()

![]()

3. Performance Advantages Of TZM Alloy Rod:

Good high temperature resistance: TZM alloy rod has high melting point and low thermal expansion coefficient, can maintain stable performance at high temperature for a long time, has excellent oxidation resistance and hot corrosion resistance, and is very suitable for use in high temperature environments.

Good processing performance: TZM alloy rods have excellent processing performance at high temperatures, and can be used to manufacture high-temperature heating devices, such as high-temperature electron guns, high-temperature furnaces, etc.

High strength and hardness: TZM alloy rods have high strength and hardness, can withstand large loads and impact loads, and are widely used in aviation, aerospace, nuclear engineering and other fields.

Good corrosion resistance: TZM alloy rods can maintain good stability and corrosion resistance in acid, alkali, salt and other corrosive media, and have good corrosion resistance.

4. Application Of TZM Alloy Rod:

High-temperature heating devices: such as high-temperature electron guns, high-temperature stoves, etc.

Aerospace field: such as engine parts, missile parts, aero-engine bearings, high-temperature bearings, etc.

Nuclear engineering field: such as nuclear reactor components, nuclear energy fuel, etc.

Petrochemical field: such as high-temperature corrosion-resistant valves, oil drill bits, pipeline connectors, etc.

In addition, TZM alloy rod is also widely used in electronics, semiconductors, medical equipment, shipbuilding and other fields, and is a very important high-performance material.

Why Choose Us:

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten and molybdenum non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tungsten alloy, molybdenum alloy and other more than 100 kinds of products.In 2010, with the surge in export sales of products in this industry, we began to focus on foreign trade export business,provide high-quality non-ferrous metal products for the international market.After years of development,at present, it has become a comprehensive non-ferrous metal production enterprise integrating manufacturing and processing, material research and development, product testing, and stock inventory.The development of nearly ten years reminds us that high-quality products and services are always our top priority,at the same time, we continue to expand into new fields and provide high-quality products and services for more domestic and global customers.Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customers.

![]()

![]()

Do you want to know more about our products?

![]()